Guia sobre com escollir una impressora 3D professional – White Paper

Currently, the market of 3D printers offers a wide range of capabilities and requirement ranges, and it can be at times overwhelming. This whitepaper should have covered all the important features that may differentiate all printers available in the market and answer all initial questions when facing the task of choosing a 3D printer. Matching your own company’s goals, needs and priorities will help you narrow the search and choose a 3D printer that fits your corporate needs.

Download here the full White Paper >

The business world has shown an incessant interest in incorporating 3D printing technologies into their workflow. Reduction in costs and time have validated the industrial usability for a technology created to deliver customized objects. This has made the Additive Manufacturing market prone to competition and the options available for businesses are endless. BCN3D has created this whitepaper to help identify the key features that will help any company choose the right 3D printer according to their business needs. This way, it will be easier for your team to identify the right 3D printer based on your company’s needs, goals and requirements. Up next is a thorough coverage of 3D printing basics and we hope it becomes the guide that covers all your 3D printing questions.

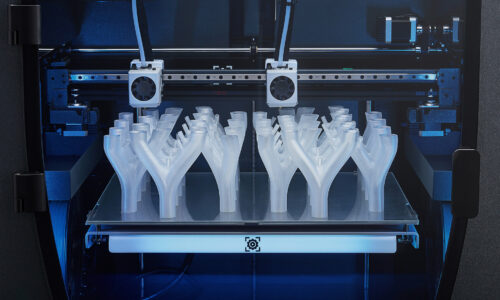

Build volume

The Build Volume is the maximum size of a model that a 3D printer can produce in a single print. Build volume is one of the most important indicators when selecting a 3D printer.

If the business need is to print large volume pieces, the company will have to select a printer with a large build volume. The versatility to produce large objects may generate a loss in accuracy and reliability, and also an increase in the final price of the printed object.

Best Layer Resolution

The layer height is the distance between one layer and the next one. The layer resolution determines the quality on the Z-axis.

The typical range of layer heights goes from 0.05mm to 0.5mm. This range is important when deciding which printer may fit your business better, as not all machines will print within the full range of layer heights.

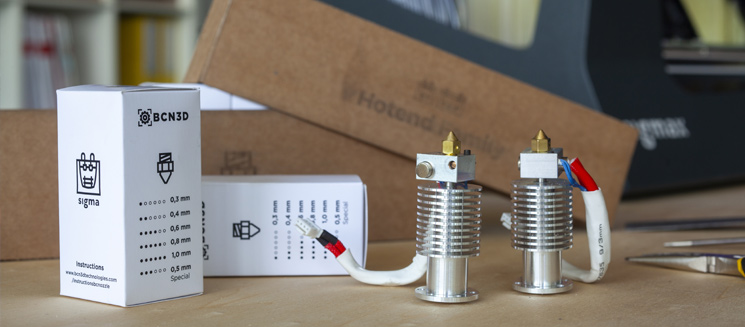

Hotends

Hotends

The hotend is the component of an FFF 3D printer that heats, melts and extrudes the material layer by layer through a nozzle.

Learn more about the parameters governing the definition of hotends in this article about Extrusion System ‘Anatomy of an Extrusion System’ here.

Since most printers accept different hotends and nozzle sizes, the important feature to check on the printer specs is how easy it is to swap hotends. Users should also make sure that the materials they want to use are printable with the compatible hotends.

Extruders

Extruders

An extruder is a motor and all the associated mechanisms that push and pull the filament to carry it from the spool to the hotend.

If you are planning to print with flexible materials, make sure the printer has enough pushing force to extrude the filament. Ask for the flexible compatible materials that the printer has.

Dual Extrusion

Dual extrusion refers to the ability of an FFF 3D printer to use two different filaments in a single print job.

There are two types of Dual Extrusion in the 3D Printing Market:

Having two extruders allows a more efficient print, as it will give the user the power of dual versatility in one machine. While some dual printers may have the ability to print with dual products, colors or properties, some printers on the market may also use the dual extrusion to produce double amount of pieces (printing on mirror mode, for example). If you are planning to print with at least two materials, colors, or want to improve your performance, consider choosing a printer with dual extruders, or even better: with dual, independent extruders.

Other important aspects to look for when choosing a 3D printer included in the whitepaper:

- Print surface

- Firmware

- Compatible materials

- Slicing Software

Extruders

Extruders