Instituto Europeo di Design accelerates students’ creative thinking with 3D printing

The Instituto Europeo di Design has been using their BCN3D 3D printers for a faster design workflow, unleashing the full creativity and productivity of their students.

The Instituto Europeo di Design (IED) is an international network of universities specialized in training, development and research in the fields of Management, Fashion, Design and Visual Communication. Since 2017, IED Barcelona has implemented BCN3D 3D printers for prototyping and functional testing, speeding up students’ creative process and turning conceptual designs into reality.

Professional desktop 3D printing at IED university

Before incorporating 3D printing technologies into their university back in 2017, students at IED were using basic equipment and traditional model-making methods for prototyping their ideas. However, hand-made models do not capture the full potential of the concept and these processes proved time-consuming and labor-intensive.

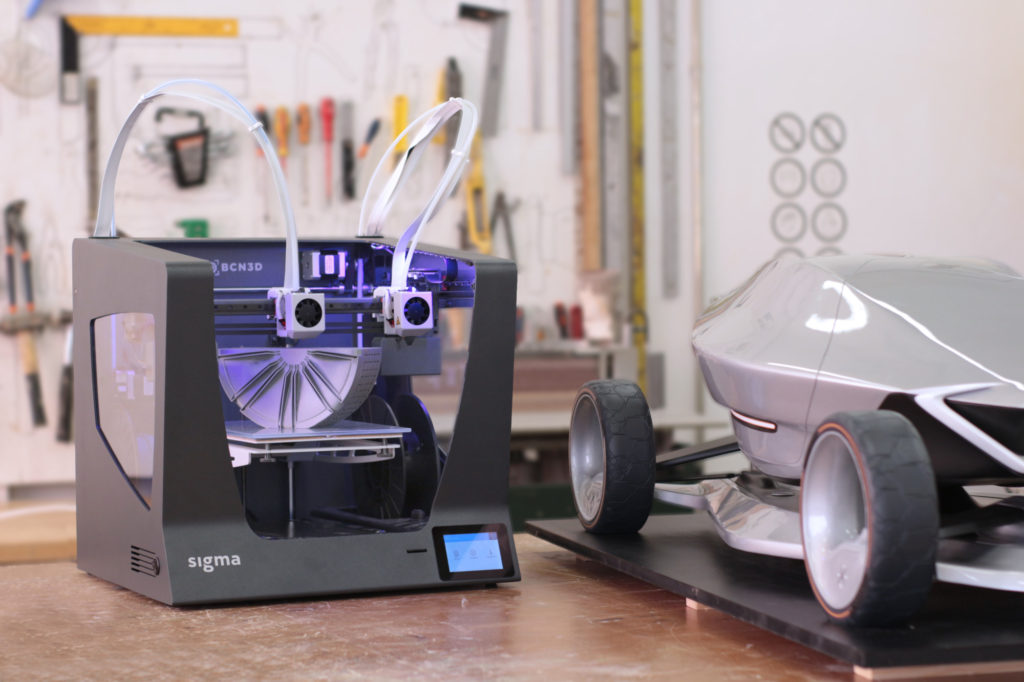

With that in mind, IED sought an on-site solution, such as 3D printing for prototyping and functional testing. They decided to introduce the BCN3D Sigma and the Sigmax R19 3D printers into their FabLab.

“The IED philosophy is a methodology based on learning by doing. Therefore, the rapid prototyping step becomes very important. During the design process, students are capable of iterating faster and achieving refined designs with 3D printed models in a very straight-forward workflow,” explains Raffaella Perrone, Managing Director of Design at IED Barcelona.

Reducing model-making time and increasing iterations

For IED students, it’s not so much about the cost of the materials, but the reduction in manufacturing time that really makes a big difference. By building the model in alternate ways to traditional methods, students avoid time-consuming processes.

Furthermore, having in-house 3D printers allows them to test more designs in a shorter period of time and also reduces the costs of making design iterations.

BCN3D 3D printers at IED Fablab

The main reason IED decided to invest in BCN3D Printers for their FabLab was IDEX technology. IDEX is the most reliable and neat solution on the market when it comes to dual extrusion technology. This is due to the two extruders that work independently when printing water-soluble supports or multi-material parts. While one extruder is printing, the second one is parked, preventing the drip of molten plastic into the part. Conventional dual extrusion printers have both extruders together, which may result in filament threads left on the piece.

IED, by using 3D printing technologies, clearly demonstrates how 3D printing can revolutionize students’ creative thinking. If your university is interested in investing in a 3D printer, learn more about how to choose the right one for you in this whitepaper.

[button link=”https://3d.bcn3dtechnologies.com/whitepaper-how-to-choose-a-3d-printer” size=”small” bg_color=”#0095ff” window=”yes”]Download guide on how to choose a 3D Printer >[/button]

Ready to save time and cut costs with a BCN3D printer? Request a customized quotation for a BCN3D Printer.