Sigma ProGen. Sigma R17

What you will read

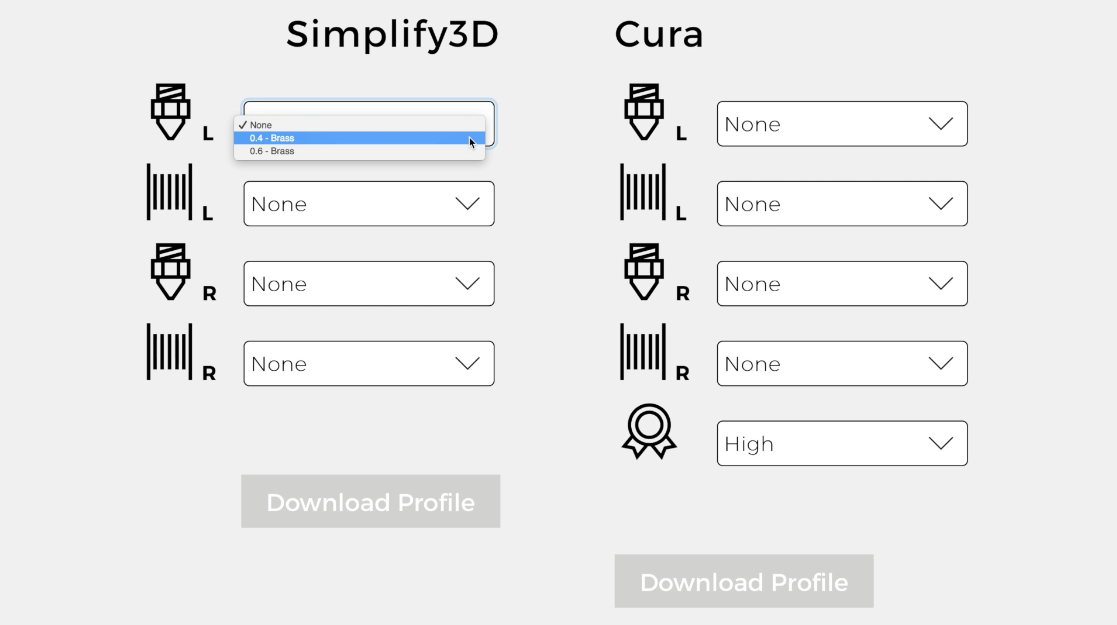

With the new Sigma R17, the new Hotend Family, new verified materials, and new quality preset, offering proper profiles for our slicers and for each machine combination was not a human task. So, we developed the Sigma ProGen which automatically generates proper profiles for Cura and Simplify3D according to mounted Hotends, loaded Filaments and quality finishes. It offers base parameters, using a smart algorithm that takes care of all the elements with one main goal: get outstanding quality on your prints while working in the fastest way.

Introducing the Sigma ProGen

In BCN3D we always want our customers to get the best quality out of their prints. That’s why we design and manufacture the Sigma in Barcelona, using high-end parts and with a Premium standard in our mind.

However, not using the proper settings while slicing your models can ruin it all. So not only we need to offer a first-class workhorse, but it’s very best slicing settings to fulfill our customers’ needs and print easily with a stunning quality standard.

Offering this settings pack is easy if you have a quite small amount of verified materials, a pair of nozzle sizes and some basic quality presets. But when the new Hotend family came to the stage, machine configurations started to grow exponentially. Then, if we wanted to expand our verified materials range, as we do, the possible combinations quickly reach to tens of thousands. And if at the end we wanted to offer a set of quality pre-configurations playing with speeds and surface finishes, this number became so big that we would need years to test all configurations. Let’s see a real-life case:

A Sigma beta tester wants to print a big part with a high detailed surface but wants it fast. He has the new Sigma R17 and just got a brand new 0.3mm Hotend, and a 0.8mm one. So, he needs a profile for Simplify3D to print a very detailed shell with the 0.3mm Hotend with Colorfabb XT, 45 microns layer height, and go fast printing the infill with the 0.8mm Hotend and a cheaper PLA, 400 microns layer height.

After this nice approach to the IDEX system capabilities, another client asks for a good profile for Cura. He doesn’t care about surface finish so much but wants to print a Dual model using Colorfila PLA and Colorfila TPU with 0.6mm Hotends.

Good. And after that, another Sigma owner asks for… Well, you can see how many combinations can exist. That means, if we wanted to offer you the optimal base settings for any Hotend combination and any materials loaded, hundreds of thousands of parameters would need to be adjusted manually.

At this point, we started considering a tool to facilitate all this process of setting up the correct parameters to slice the models and generate the codes. We needed something where our customers can say “I have X Hotend combination on my Sigma, Y materials loaded, and I want the final part to be printed with Z quality” and then give them the best base settings available.

The good thing is filaments’ behavior can be mathematically modeled, so do our Hotend designs and of course, the quality presets we offer. Therefore, we needed a smart enough algorithm to combine all these variables and deliver the best settings for each possible combination. Not just that, but we wanted it to be modular, so we could add new Hotends, new verified filaments, or custom quality presets to the database and keeps getting awesome profiles. And of course, we wanted it all to be transparent to the final user.

So here we go, very proud to introduce our new tool Sigma ProGen. A web-based profile generator for both Cura and Simplify3D to get the best of our Sigma machines.

To use it:

1. Select how you want your profile and download it.

That’s it. Plug and play.

Using a web interface allows us to make sure all our customers can always have the latest adjustments and filaments available. Also, we know some special prints may need specific tweaking. That’s the reason why we offer a base profile that delivers highly successful results, while at the same time it allows everyone to adjust all parameters in the software before the slicing starts.

Nevertheless, we know some of our customers prefer to work offline. That’s why we have developed a command-line interface to use the algorithm locally. This software is available to download from GitHub and allows to locally generate all the desired profiles, absolutely offline. Also, it offers some experimental features we’re currently developing at BCN3D so everyone can test them and give their feedback.

Stay tuned for the upcoming posts, where we will go deeper into how the algorithm works and how to add your custom filaments, quality presets, or even Hotends!

And give us your feedback about the ProGen!