BCN3D Slicing Guide 2: Aligning line width with your application’s needs

Our second installment in our Slicing Guide, in collaboration with Flowalistik, brings you a wealth of knowledge on Line Width; specifically, the different outcomes you can achieve by altering the line width in relation to surface details, bed adhesion, and mechanical properties.

A great 3D printing experience requires more than just making great hardware. At BCN3D we’ve developed BCN3D Cura, an advanced slicing software that allows you to make the best out of the BCN3D printer and material family.

If you struggle with 3D printing models that include text or have thin walls, the Line Width settings will help you achieve a better print quality. In this post, we’ll learn everything about Line Width and how it affects the 3D printing process.

What is Line Width?

The Line Width setting represents how wide the filament lines are extruded. This setting is usually the same as the nozzle diameter. However, it’s possible to extrude thinner and thicker lines by playing with this setting. For example, if you’re using a standard 0.4mm nozzle, you could set a line width of 0.3mm or 0.5mm.

This setting has many effects on the 3D printing process, including surface details, bed adhesion, and mechanical properties.

Line width applications

Surface details

When your 3D model includes surface details that are smaller than the hotend size, BCN3D Cura ignores them. However, if you slightly reduce the Outer Wall Line Width, you may print those features successfully.

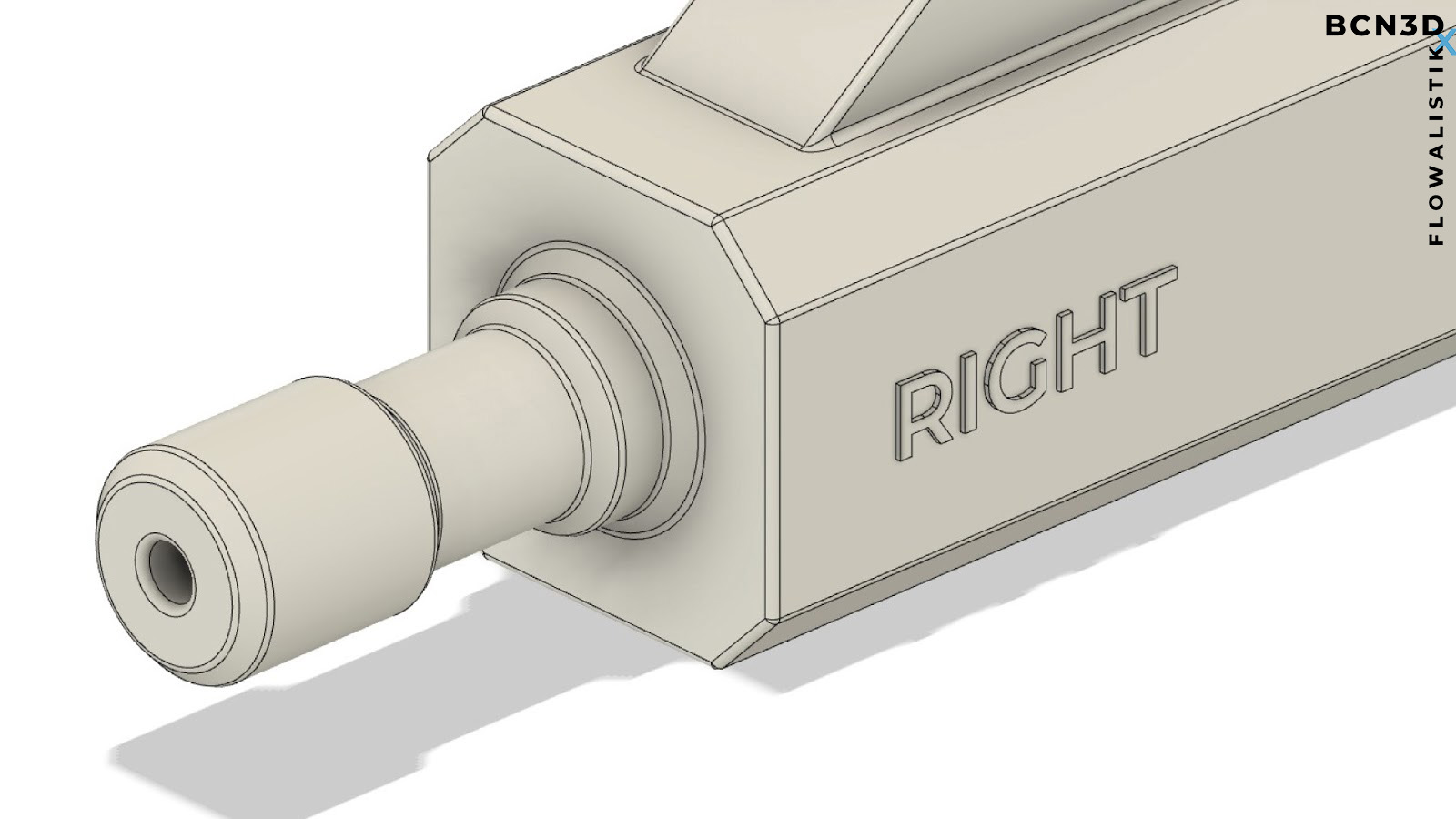

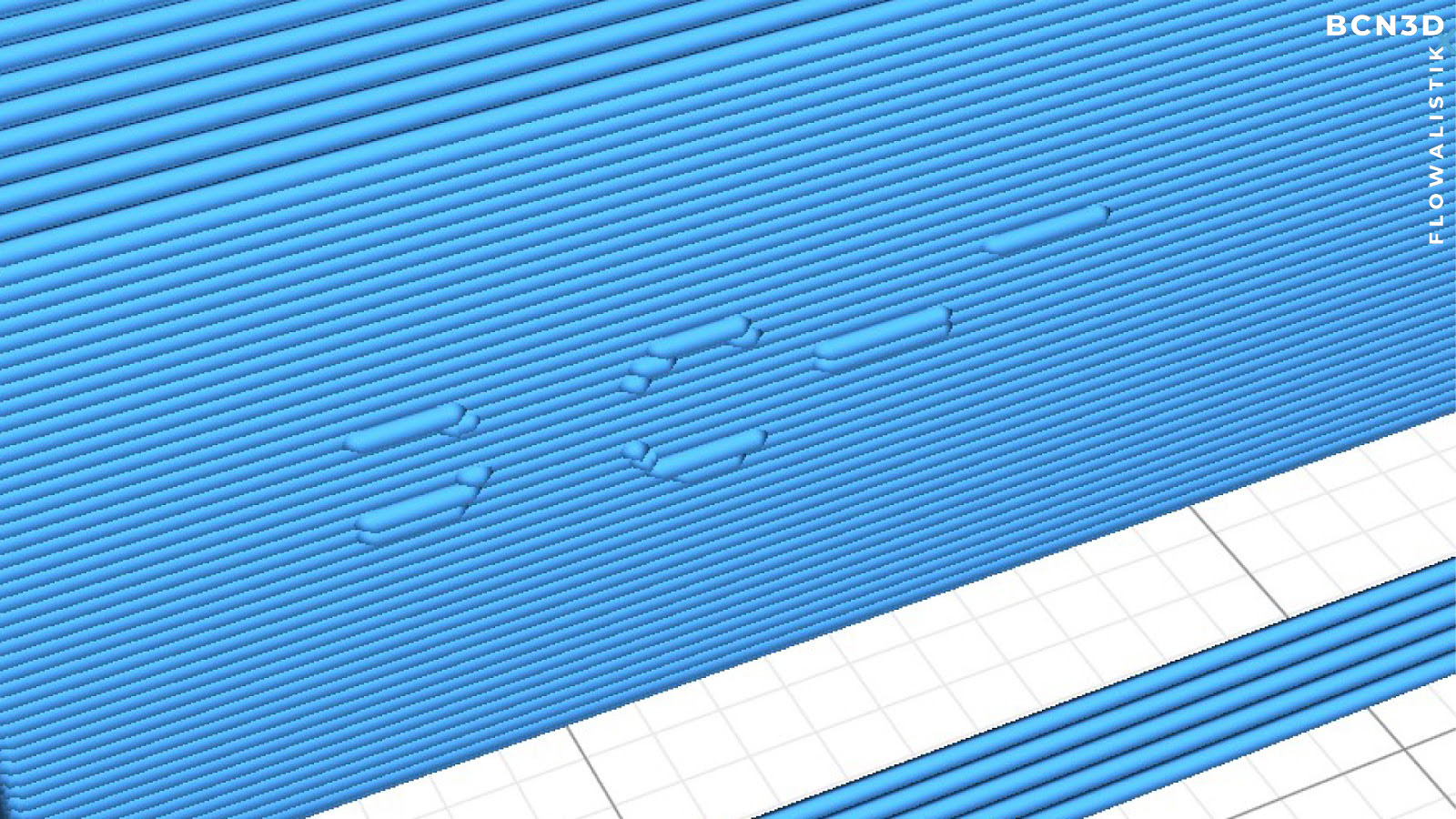

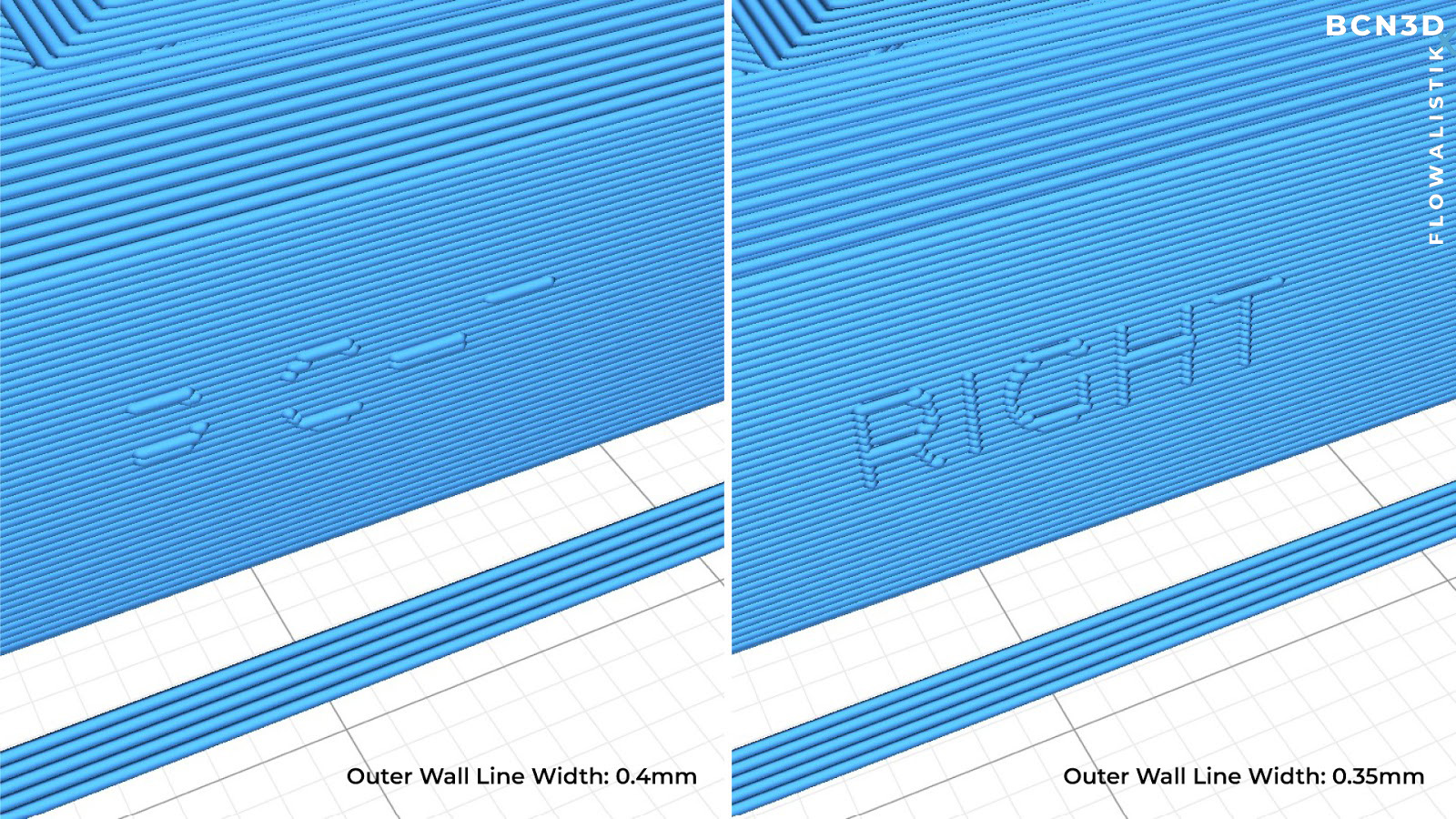

For example, many 3D models include text that offers indications when using the product. The product from the image below has two almost identical components. One must go on the right and the other on the left.

The design is optimized for 3D printing. However, when slicing the model in BCN3D Cura, the text disappears as the stroke thickness isn’t large enough.

This is a prevalent issue with text features, as the stroke thickness should always be larger than the Line Width. In this case, the problem is solved by slightly reducing the Outer Wall Line Width from 0.4mm to 0.35mm.

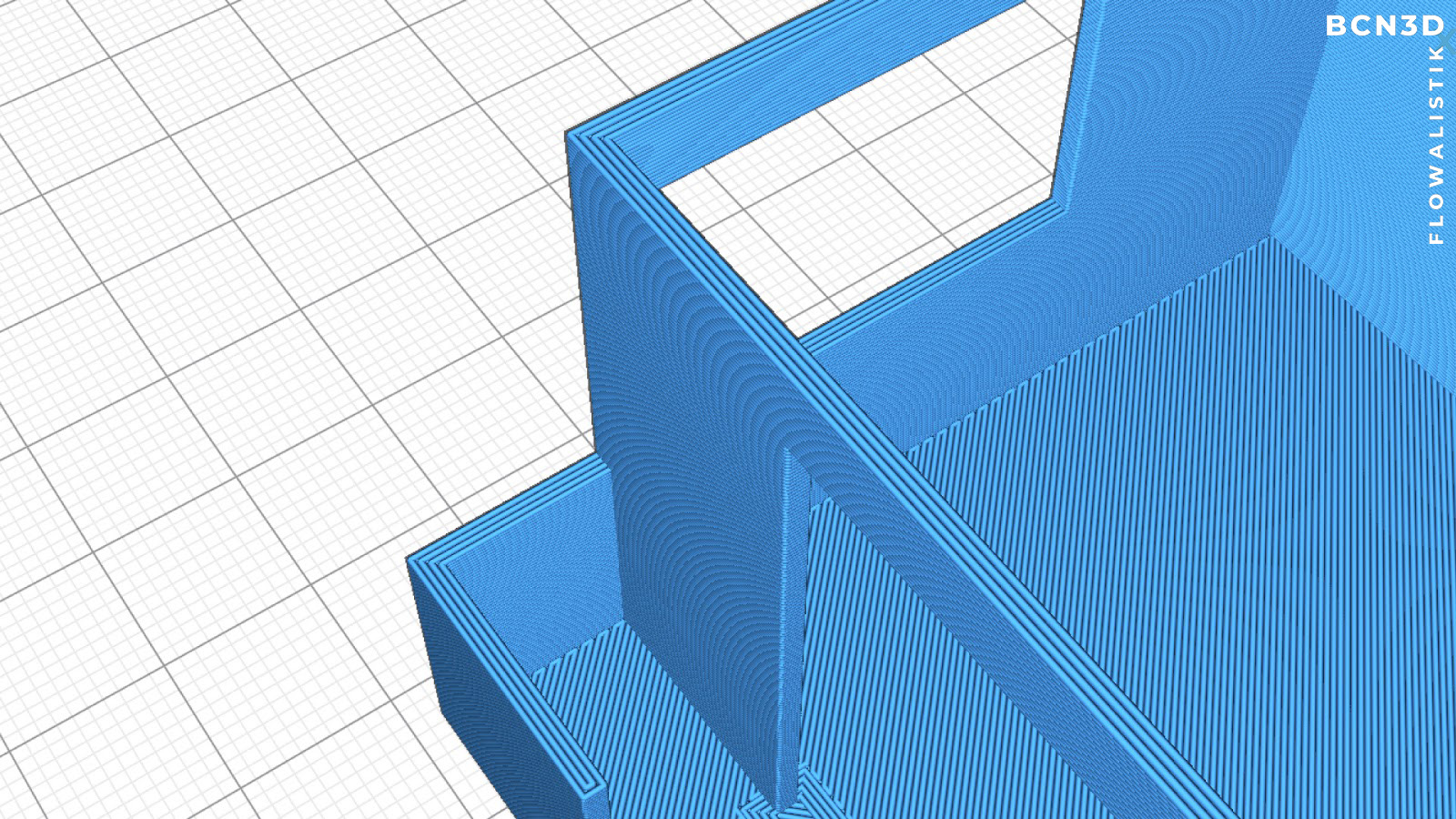

The Line Width settings are also helpful in those cases where complex shapes and textures need to be printed as one single part. For example, architectural models usually include vertical walls that have a variable thickness. In those cases, using a smaller Line Width can help achieve better overall quality.

Bed adhesion

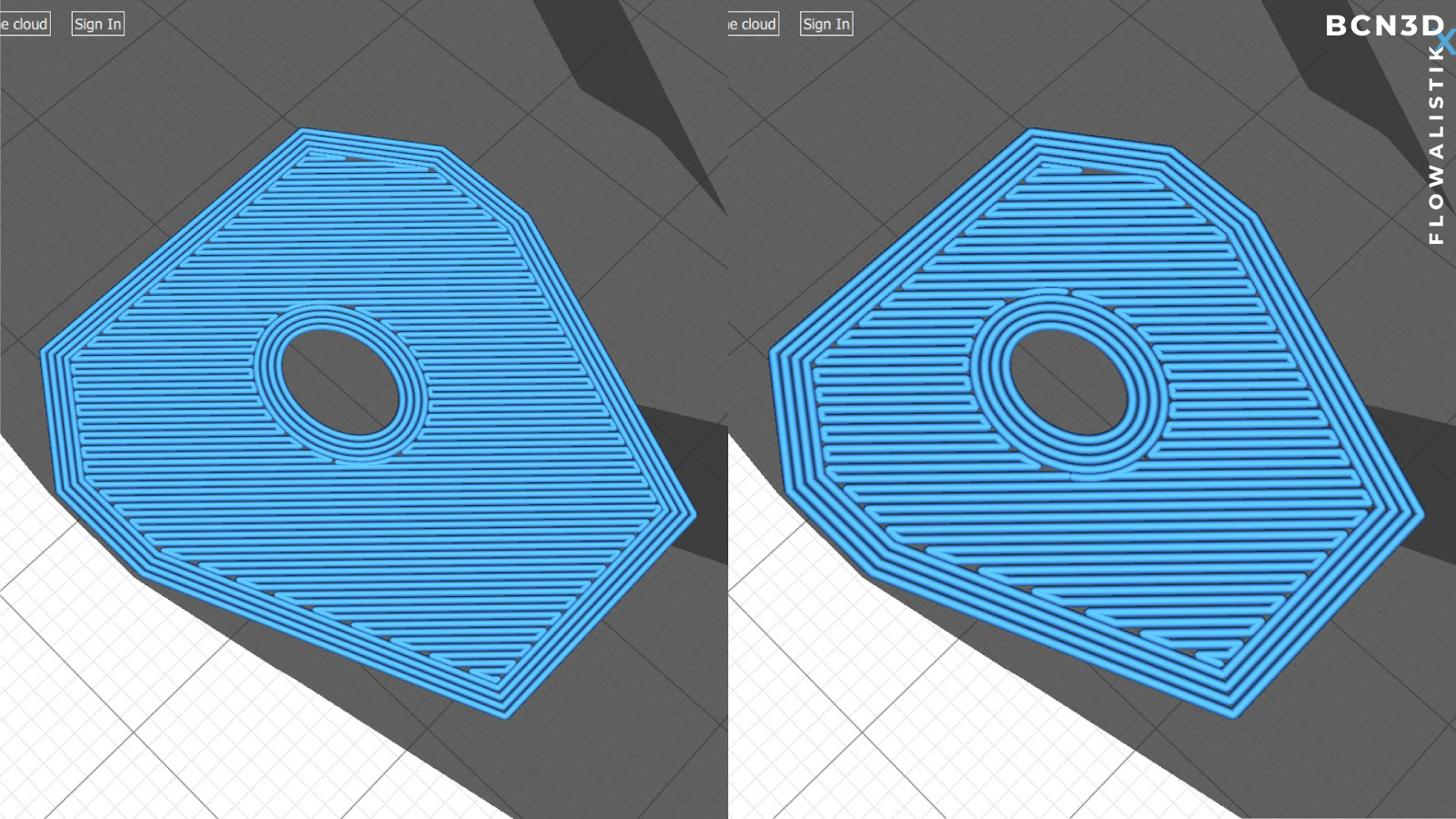

The Initial Layer Line Width setting increases the first layer’s line width, affecting all the line widths. As more material is extruded in the first layer, it’s pressed harder against the build plate, increasing the adhesion.

Mechanical properties

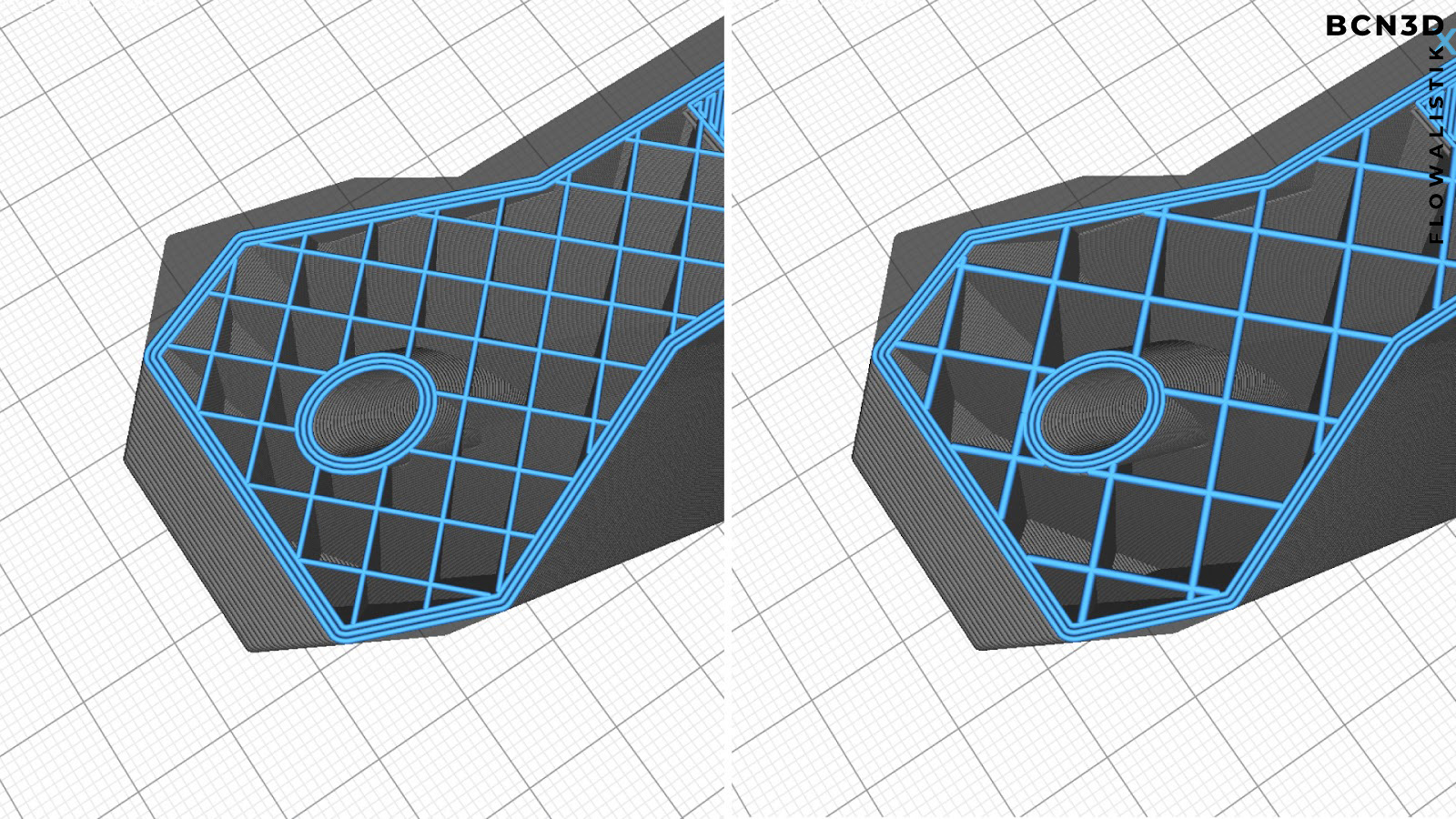

Make small adjustments to the part strength by increasing the Infill Line Width from 0.4mm to 0.6mm instead of increasing the infill percentage. This way, your part’s infill will be thicker and more resistant while the print time remains the same.

The two main benefits when increasing the Infill Line width are:

- Reduced print time: The number of infill lines reduces, which also reduces the print time.

- Increased strength: Using larger hotends or Line Width leads to an increase in part strength.

Slicing considerations

Even though it’s possible to improve the print quality by modifying the Line Width settings, it’s recommended to find the right hotend for your print. Different hotends are available for the Epsilon and Sigma product families.

To continue deepening your understanding of the importance of Line Width and how it can affect surface details, bed adhesion, and mechanical properties, be sure to read our dedicated BCN3DxFlowalistik white paper, or download our all-in-one ebook featuring all 6 slicing guides below.