BCN3D Sigma printing with water soluble supports

In this post we will see how to get a perfect print of parts with complex geometries, with overhangs, using support structures of water-soluble material. All this in only one print thanks to the double extruder system of the BCN3D Sigma. Furthermore, we will show you two videos where you can see the printer manufacturing parts with water-soluble material and how they are subsequently dissolved in water.

The manufacturing system of FFF 3D printers (Fused Filament Fabrication) relies on additive manufacturing by melting plastic, ie, by adding plastic material through a nozzle that creates layers from the bottom to the top of the piece. In this video you can see a timelapse of a printed piece by FFF 3D printing technology. This technology has a limitation: the overhangs on the pieces that we want to print. An overhang is any element of the piece that protrudes at a certain angle. This means that if we have a part that have overhangs in certain zones, in these zones, the molten plastic material coming out from the hot nozzle will fall due to the gravity. There is a solution to avoid material falling down: create a structure of supports to hold those zones.

The supports structure is automatically generated by the printing software. In the case of Cura, you can adjust certain parameters of the supports as the density of these, the minimal angle that overhangs need to have to get support, etc.

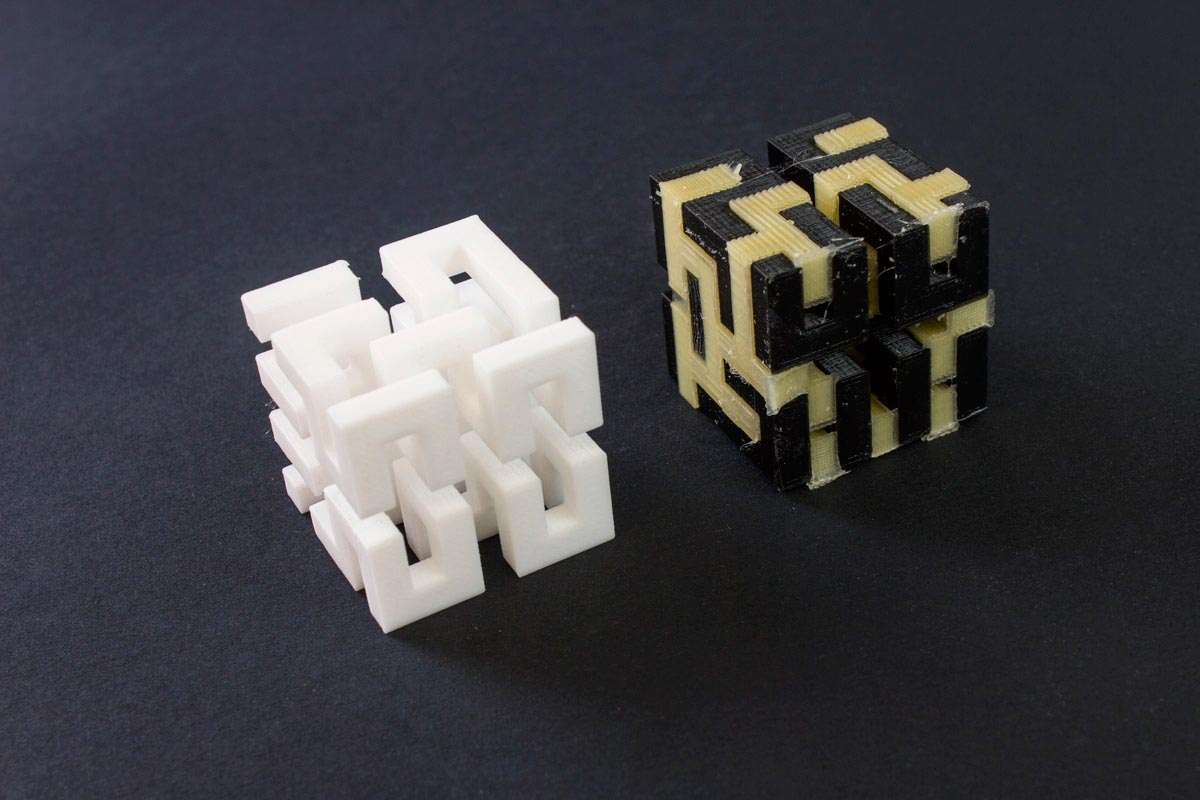

The problem that arises with the supports if your printer has only one extruder is as follows. Suppose we want to print a piece that has overhangs and therefore will need support structure. Having a single extruder implies that both the printed piece as the supports must be of the same material. Thus, once we have the printed piece will be necessary to remove the supports manually, for example with pliers. The problem we will face is that the printed piece will have imperfections in the zone where the supports and the piece were touching.

Another option is to have a printer with two extruders. Thereby, we will make the piece with the first extruder and the supports are made with the second extruder with a water-soluble material. A water-soluble material is one that can be dissolved in water, like PVA (Polyvinyl alcohol). Thus, once printing is completed we have a part of, for example, PLA, and the supports will be of PVA.

To remove these supports, we put the piece in water and after a few hours the PVA will have been dissolved. In this way, we have our final piece without imperfections and with the contact zone (between the supports and the piece) smooth and without trace of PVA supports. This functionality is available on the BCN3D Sigma, our dual independent extruder printer that allows the use of the second extruder for building the supports.

We have prepared two videos so that you can see it. As you will see, once printing is finished, we put the piece in an ultrasonic cleaner machine with water to speed up the process and to dissolve the supports faster. In the first video we were printing a piece of extreme complexity designed by Dizingof, an expert in the Math Art, among other things. In the second video we were printing a mechanical part of a car that requires of supports, it is a knuckle. The configuration that we have used for printing these pieces is available in the profiles folder of our customized software BCN3D Cura.

Try it and print your most complex piece with the BCN3D Sigma using water soluble support material and share it with us!

https://www.youtube.com/watch?v=QymTct1xyO8