BCN3D Sigma, the evolution of our flagship

As it happens with all the inventions in history, our BCN3D Sigma has experienced several changes, in a technical and esthetic way, from its conceptual formulation to its present shape and configuration. In this article, we will focus on the first aspect, which will the user to better understand why the BCN3D Sigma looks like it does.

Conceived in a little bit more than six month –always talking about its shape and esthetics-, we can affirm the BCN3D Sigma went through infancy and puberty in a record time, taking into account the product design parameters.

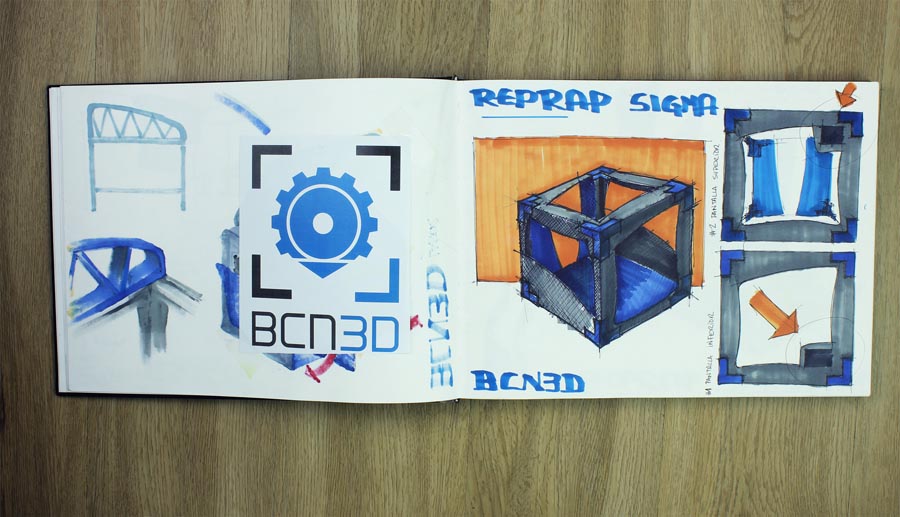

In the first instance, the BCN3D Sigma had a much simpler structure, a cube of aluminum profiles that much could remind us of another of our 3D printers, such as the BCN3D +.

Nevertheless, it didn’t take too long to reject this design for a reason as simple as a change of the target. From the very beginning, at BCN3D Technologies, we knew the target for the Sigma would be different than the one for the BCN3D+, so both printers had to be visually different. While the BCN3D+ was intended to attract an educational and maker public, the Sigma was though for the professional sector, and it should look like so.

About the same time, we started developing another two machines, intended to position BCN3D Technologies in the market: the BCN3D Lux and the BCN3D Ignis. In that situation, and with the intention of creating a corporative image, we decided the three machines should have unified aesthetics. Thus, the overall geometric of the BCN3D Sigma as we know it nowadays was decided.

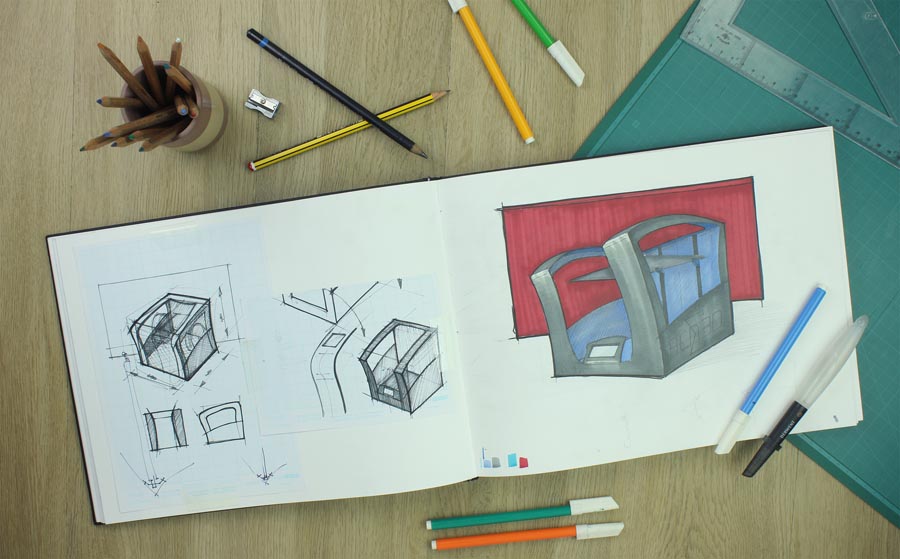

However, the process was far away from being finished, because we still needed to decide many structural aspects –definitive shape, materials, etc.-, in which decision we have to count a lot of variables, as its functionality, assembling time, costs, among many others.

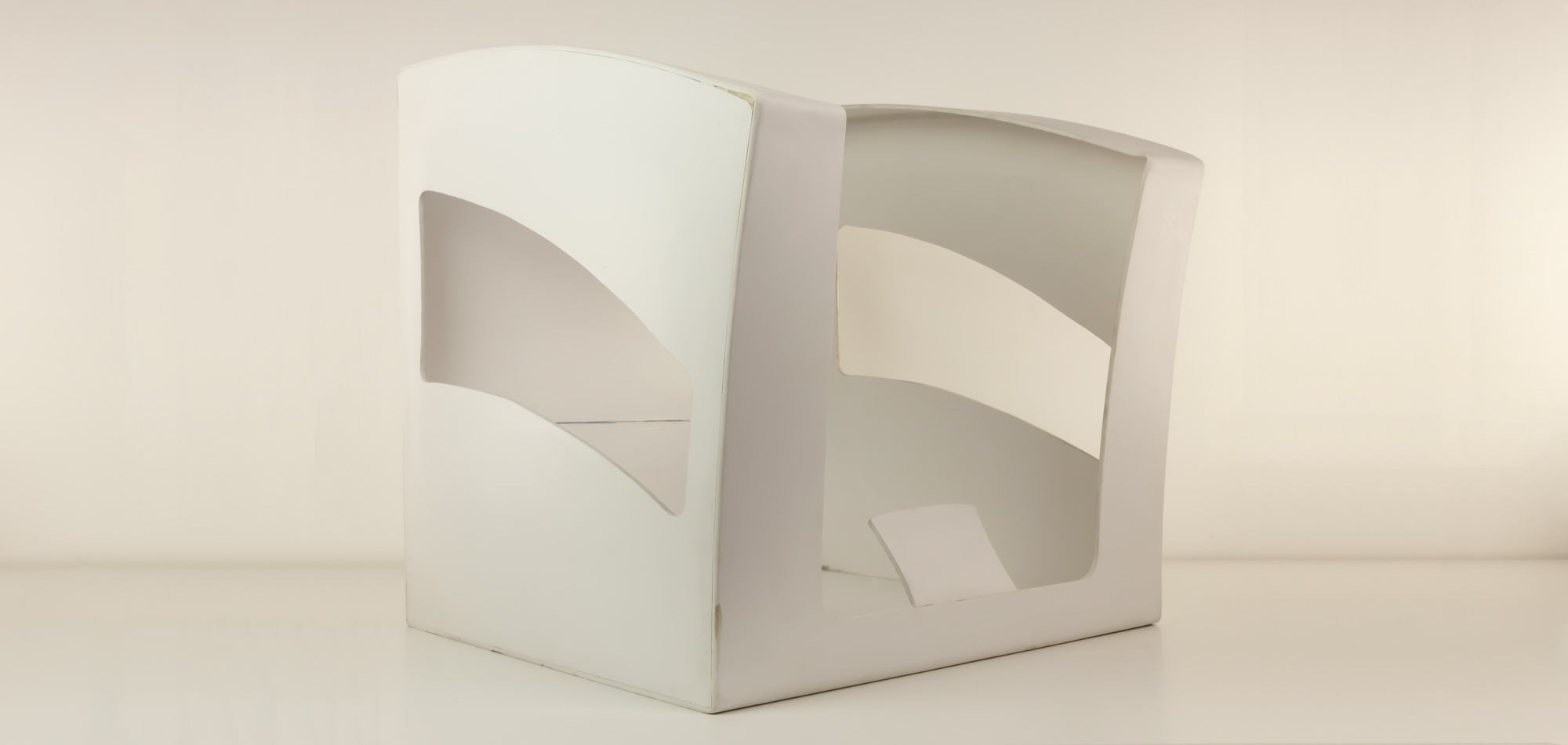

As usual on a new product design and development, to find the perfect esthetics for the BCN3D Sigma we needed a prototype on which to work. For that reason, we created a foamed PVC mockup, which we used to identify some viability problems for its fabrication – the bent arms were discarded for mass production of the machine- and functionality -the screen placed in the center of the structure was not practical-.

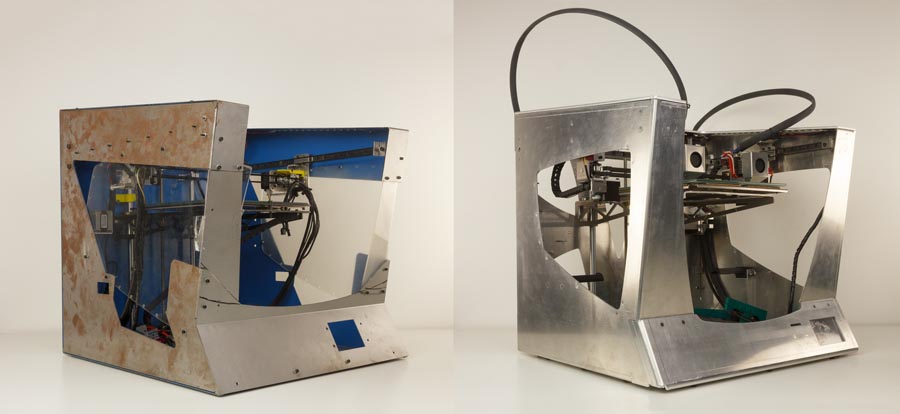

With these first changes, we could fabricate the first functional BCN3D Sigma prototype, which exterior structure was made of different screwed steel sheet, which was unattractive and impractical, and too heavy. For that reason, the next model, still made with separate parts, had the screws hidden in its interior face, thanks to what its structure was less heavy and unwrinkled.

Finally, in a third structural evolution, we opted for a single welded aluminum sheet, which was much more practical for its assembling and easy in the eye, presenting curves that distinguish the BCN3D Sigma from any other printer. From that model we started working on the details, like the position and shape of the LCD screen with which you manage the machine, or its exterior structure colors.

As a result from this process, we created a 3D printer that not only stands up in the market for its technical characteristics, as it can be its independent dual extrusion system, but also has a unified aesthetics with the BCN3D Ignis and Lux, rising up as the flagship of the corporate identity of BCN3D Technologies.