Will 3D Printing Replace Traditional Manufacturing?

The manufacturing industry and 3D printing are a dream team. Manufacturing is an ever-growing industry, and 3D printing is now at the lead of many advancements and innovative techniques.

We asked David Trillo Hernández, a member of our very own technical team, for his predictions on the future of manufacturing with additive manufacturing tools, and the effects we’re seeing today.

In this article, we’ll examine the impact that 3D printing has already had on the manufacturing industry. We’ll also explore the possibilities of the evolution of this function in the industry.

3D Printing and Manufacturing, Today

Currently, 3D printing has many different applications within the manufacturing industry, such as producing precise tools, fixtures, and prototypes.

As a solution, 3D printing is very valuable in the manufacturing industry for its ability to quickly adapt to needs and ideas, especially in producing objects that speed up production chain processes. Specifically, when it comes to creating tools and fixtures that can promptly adapt to unique needs.

Traditionally, prototyping can be costly and time-consuming. You would either have to contract an external manufacturer or spend time and resources creating the prototype in-house. Now, the increase of 3D printers in manufacturing plants has sped up the prototyping process. It also has a lower cost, higher confidentiality, and a smaller environmental impact.

A good example of this is Renault. Renault formed a 3D printing hub within their company that allows them to produce necessary tools, fixtures, and prototypes without having to rely on an external manufacturer. The hub does not have one specific application, but instead, they utilize 3D printing for a variety of requests. The value of this is akin to having a dedicated workshop within your own company.

However, while it is an essential part of manufacturing processes currently, 3D printing is not yet utilized on a wide scale to create full-blown final, end-use products.

The Future of Manufacturing

In the coming years, we expect to see 3D printing used to create more final use products. With the growing market demand for customized and personalized products, we predict that the role of 3D printing will increase exponentially, as this technology allows for greater flexibility in customizing products without adding a huge cost.

Let’s take a look at car manufacturing as an example. If a consumer needs a car with a customized steering wheel, this would normally be a very costly and time-consuming addition to the manufacturing process.

However, 3D printing could provide the possibility of creating the personalization straight from the manufacturer at a much lower cost and time expense than if done through other traditional methods. This could be a reality in the near future, when the material is as strong and meets the same quality standards as today’s final use products.

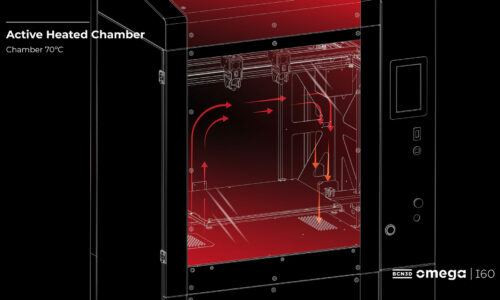

We also anticipate that the ease of use of industrial-grade materials will change over time as well. We have already seen this in recent years with ABS.

Just a few years ago, printing with ABS was considered to be tough and not for beginners. However, this filament has evolved to make ABS a very commonly used material. We expect that we can see a similar evolution to occur with many other materials.

Will 3D Printing Ever Replace Manufacturing?

Will 3D printing ever actually replace traditional manufacturing? It’s a fair question when you consider how quickly it has already revolutionized the industry.

Potentially, many, many years from now 3D printing will expand to replace traditional manufacturing as we know it today. However, this is not likely something we will see in our lifetimes. In the near future, 3D printing could potentially significantly modify some processes within the industry.

Rather than seeing 3D printing as a potential ender of manufacturing as we know it, we see 3D printing as a way to expand the field of manufacturing beyond what we can currently even imagine.