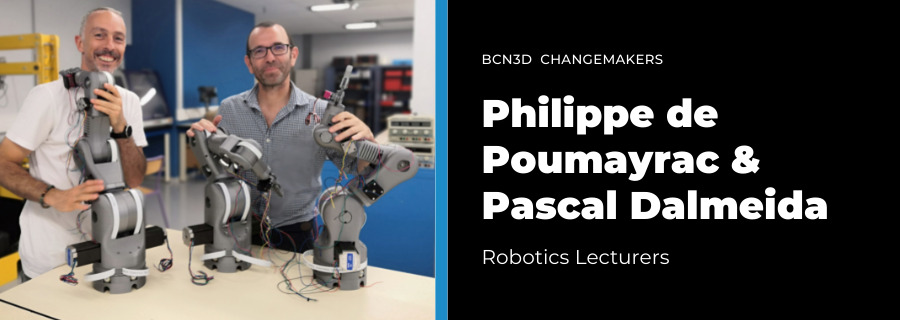

Ecole des Mines d’Alès’ 3D printed 6-axis robot arm

We are two teachers that have been teaching Industrial Engineering Sciences for around 20 years. After a few years in the Paris region, we landed in the Montpellier Academy, at Albert Einstein high school in Bagnols-sur-Cèze. Since October 2017, we’ve also been teaching Robotics at the Ecole des Mines d’Alès to future Mechatronics engineers.

Focusing on our students

When we arrived at the Ecole des Mines d’Alès, we were provided with two 6-axis industrial robotic arms of the UR5 type (Universal Robots) to ensure our practical work in Robotics.

After the wonder of such a big investment (of around 40.000 €), we noticed quite quickly that our engineering students were bored! After a few hours of use, the students came to the realization that they could not modify the control of these industrial arms and thus test the results of their calculations.

The main thought running through our minds was: “How can we position practice at the heart of teaching robotics when the cost of acquiring an industrial arm is several tens of thousands of euros?”. And so, in 2018, we then made the decision to design our own articulated arm and its control. Alongside a number of innovative projects to keep students engaged, we made it our mission to keep our students engaged.

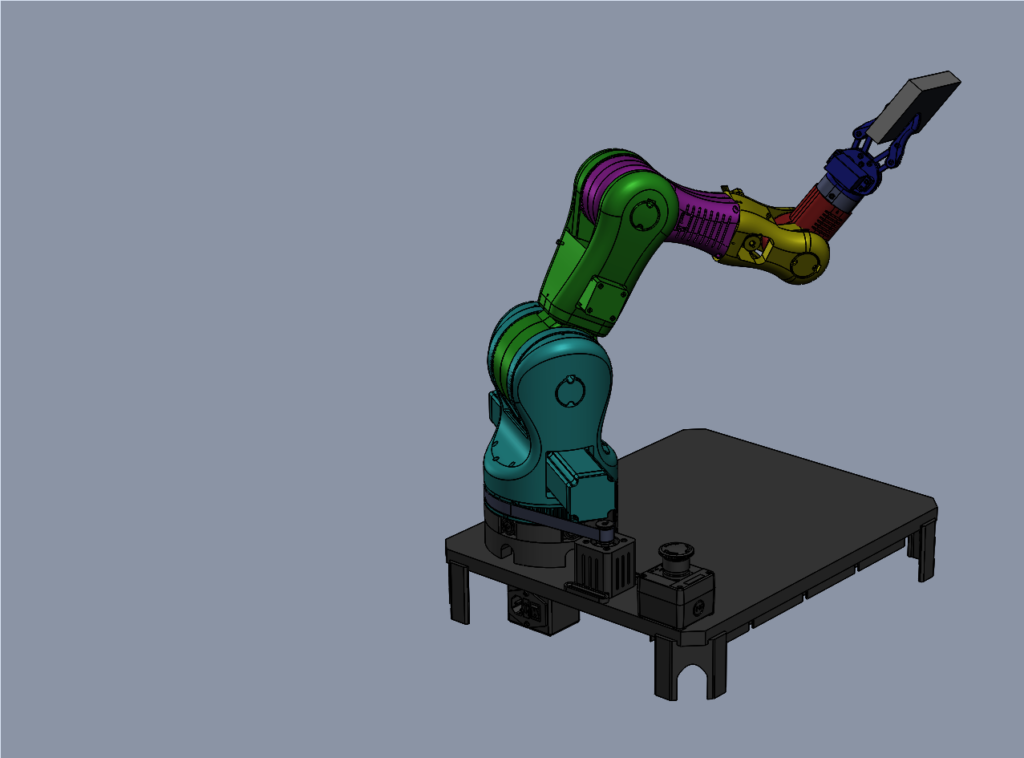

At first, we considered buying educational arms manufactured by the French company Nyrio, but we weren’t sure we could modify the order. In addition, the dimensions and the “toy” aspect put us off. Above all, we wanted to have complete control over the mechanical and control parts of our arm so that they could evolve according to the needs of the users: our students. Subsequently, we relied on BCN3D’s open source MOVEO to develop our arm.

Getting into 3D printing

The creation of the arm was made possible by 3D printing. Firstly, with the use of CAD software, SolidWorks, which seemed obvious to us! It allowed us to make the arm very modular and adaptable to the need and to make it evolve according to the technical constraints and the feedback from the users.

To allow our students to work in a practical and concrete way on a robotic arm, we had to multiply these arms and accept the risk of breakage. 3D printing was the clear solution!

3D printing (FDM) with the printers in our workshop allowed us to easily and quickly make a prototype and validate the feasibility of this project.

We would like the manufacture of the arm to be accessible to everyone. The use of PLA strongly limits the cost of the material (less than 25 €/kg) and the purchase price of the 3D printer (from 200 €).

Also, the reduced manufacturing cost of this arm allows the purchase of several arms for a low cost and allows our students to have easily at their disposal a 6-axis articulated arm and its control.

The parts, including those 3D printed, are then assembled and motorized by the students themselves.

Operating the arm

The use of Scilab to control the six joints of our arm allows each user to have access to the control of the arm in a simple and fully programmable computing environment. Scilab, the free and open source equivalent of Matlab, is distributed under the GNU GPL.

In order to move towards more sustainable development, we have chosen to source our 3D printing filament from a French manufacturer Francofil.

Nowadays

In 2022, the headmaster of the Lycée A. Einstein High School, Mr. Feutry, entrusted us with the realization of the first series of four arms to make them available to the different teaching sections of the technical and professional high school.

After the purchase of the first series of arms by the Ecole des Mines d’Alès, each engineering student can work in a practical way on a robotic arm. Future engineers can thus test their calculations in practice and immediately see the effect of their modifications on the arm’s behavior.

The arm has transformed the way the students work and keeps both the students and teachers on their toes. Learning apace with the students, teachers too need to stay updated on the latest innovations in robotics.

We’ve established partnerships with other schools, to provide the robot arm at a cost price. In exchange, high schools test out the arm with their pupils and provide us with feedback.

Our long-term objective is to offer this arm as an open-source tool so that each student and teacher can build their own arm.

What we can look forward to

From the very beginning of this project of mixing mechatronics with 3D printing, we were certain that this project could put practice back at the heart of the teaching of robotics, regardless of the age or level of our students.

We are therefore looking for partners to contribute to the evolution of this arm, develop activities around it and fulfill its potential across both training centers and industrial-level companies. We’re confident that its accessibility, low acquisition cost, modular use of 3D printing, and open and configurable control system will act in our favor. Not only that, but it is modular through the use of 3D printing and an open and configurable control system. We want to make robotics accessible to all!