BCN3D OMEGA I60

Built for the factory floor

-

![]() IDEX Technology Double your productivity by using both toolheads simultaneously.

IDEX Technology Double your productivity by using both toolheads simultaneously. -

![]() Active Heated Chamber up to 70ºC (158 ºF) Control chamber temperature for part uniformity, dimensional accuracy, and mechanical properties.

Active Heated Chamber up to 70ºC (158 ºF) Control chamber temperature for part uniformity, dimensional accuracy, and mechanical properties. -

![]() Material Operations System Integrated temperature and humidity-controlled system that prepares filaments for printing.

Material Operations System Integrated temperature and humidity-controlled system that prepares filaments for printing. -

![]() Powerful Extrusion System 1.75mm direct-drive Bondtech extruder and easy-swap nozzle change.

Powerful Extrusion System 1.75mm direct-drive Bondtech extruder and easy-swap nozzle change. -

![]() Massive Print Volume of 60 Liters Create big robust parts with solid mechanical properties.

Massive Print Volume of 60 Liters Create big robust parts with solid mechanical properties.

Are you considering a BCN3D Omega I60?

Watch BCN3D Omega I60

make its debut

A glimpse into BCN3D Omega I60’s specifications

BCN3D Filaments Ø 1,75 mm

The new Omega BCN3D Filaments have been specially formulated to ensure the best printing performance and repeatability when used with a BCN3D Omega I60.

Printed Parts

BCN3D Omega - Technical specifications

-

BCN3D Stratos

BCN3D Stratos is a straighforward slicing software, designed for speed and efficiency while still ensuring top-quality prints for a powerful 3D printing process. The user-friendly interface is free and compatible with all BCN3D Omega, Sigma and Epsilon printers.

-

BCN3D Cloud

The BCN3D Omega I60 3D printer is equipped with the latest connectivity features. Easily send your print files when connected to the network for a hassle-free workflow with our BCN3D Cloud platform. And forget about manual firmware upgrades thanks to Over The Air (OTA) updates, who will ensure that your printer is always up to date (activated on demand).

-

Knowledge base

An ever-expanding repository of tips and tricks sourced directly from our 3D printing specialists.

-

BCN3D Academy

With this online course, you will obtain all the knowledge and necessary skills to make the most out of your printer.

-

Support service

Get human service when you need it from a BCN3D expert. Our support team will make sure you take the most out of your printer.

Full product datasheet: Link

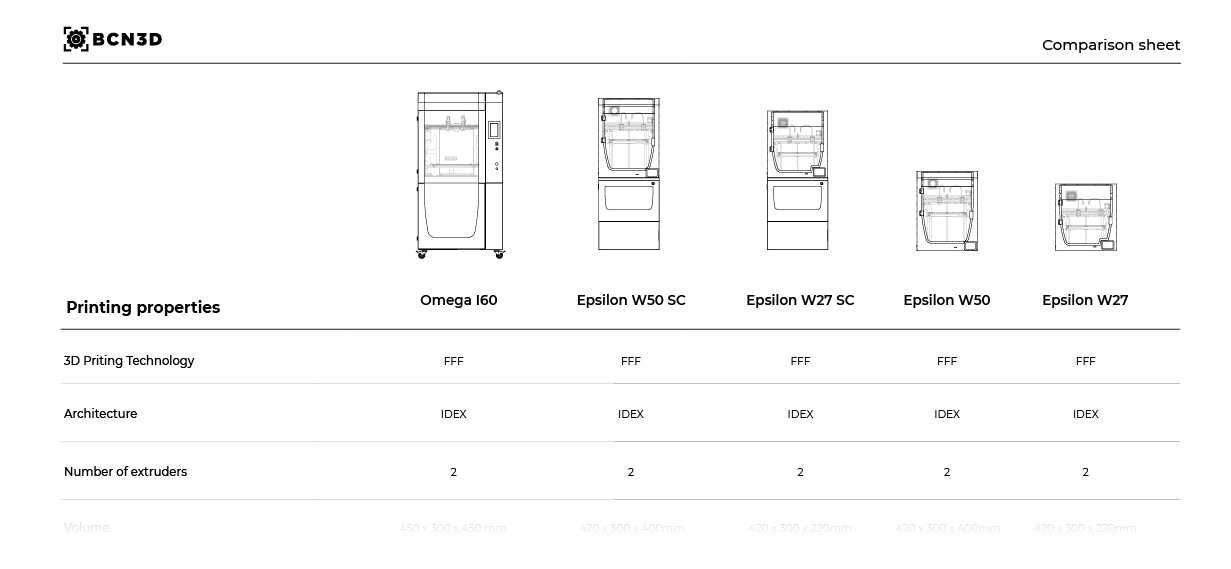

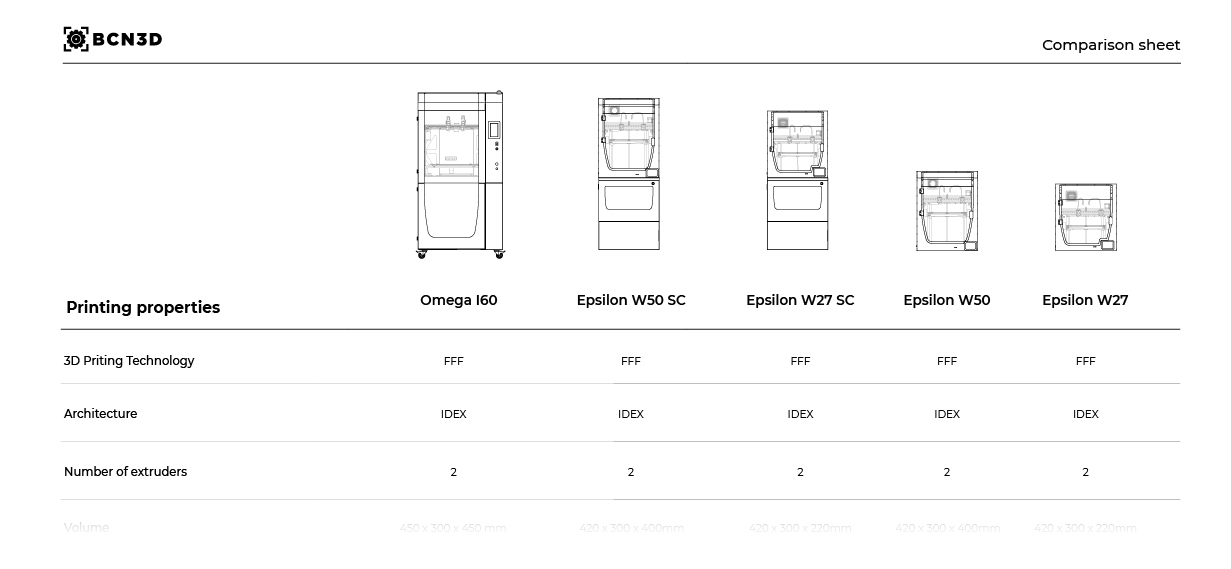

| Technology | FFF (Fused Filament Fabrication) |

| Architecture | IDEX (Independent Dual Extruder system) |

| Printing volume | 450 x 300 x 450 mm (17.7 x 11.8 x 17.7 in) |

| Filament diameter | 1.75mm |

| Tip/Nozzle | Omega Hotend Tip 0.4 HR (0.4mm) (Included) Omega Hotend Tip 0.6 HR (0.6mm) (Sold separately) |

| Calibration System | XYZ assisted calibration |

| Materials | BCN3D Filaments (for Omega) Open Filament Network (for Omega) Custom Materials (with free license activation) |

| Connectivity | Offline printing: USB Online printing: Wifi or Ethernet |

| Build chamber | Heated Chamber up to 70 ºC (158 ºF) |

| Materials Operation System (MOS) | 70 ºC (158 ºF) max temperature Average relative humidity <10% |

| Slicer | BCN3D Stratos |

| Cloud | BCN3D Cloud (Library, Queues, roles and permissions, statistics) |

| Extrusion system | Direct drive bondtech LGX Pro extruders |

| Warranty | 1 year (Extended warranty plans available on demand) |

FAQS

-

- Does the BCN3D Omega I60 have a dedicated material portfolio, and is it compatible with third-party filaments?

Customers have three pathways to choose from when selecting a filament for their Omega I60:

1. BCN3D Filaments: These materials have been carefully tailored to meet the most demanding application standards. They are designed to offer a well-balanced blend of material quality and printer performance. BCN3D provides pre-configured print settings for these materials in their BCN3D Stratos slicer software, based on extensive research and development characterizations. An Omega Open Filament License (OOFL) is not required for using these filaments.

2. Open Filament Network (OFN) for Omega: BCN3D works in partnership with material manufacturers to ensure the compatibility of non-BCN3D materials with the BCN3D Omega I60. This collaboration involves the development of specialized print profiles, which are then made accessible to users. These materials cater to niche applications with materials that offer unique properties like ESD, flame retardant, or food-safe. The pre-configured print profiles are integrated into the BCN3D Stratos slicer software and are a collaborative effort, developed by the filament manufacturer and rigorously tested and approved by BCN3D. The first filament references are expected to be published in Q1 2025. An Omega Open Filament License (OOFL) is not required for using these filaments.

3. Third-party filaments: The Omega I60 is an open material platform that offers customers the flexibility to use custom materials and create their own printing profiles at no extra cost, thanks to a free license activation. An Omega Open Filament License (OOFL) is required for using these filaments. For more information: https://3d.bcn3d.com/bcn3d-omega-i60-omega-open-filament-license

-

- What does the Omega Open Filament License (OOFL) include?

This free license unlocks Omega for printing with third-party filaments and also allows customers to personalize the print settings in BCN3D Stratos slicer software:

1. Personalize print settings: The BCN3D Slicer software Stratos comes with locked print settings by default when printing with a BCN3D Omega I60 3D printer and with pre-configured print profiles for BCN3D Filaments and for the OFN filaments. The only adjustable option by the user is the part’s strength, which can be modified using a slider that ranges from Lighter to Stronger. This slider internally affects the print settings, including infill, top and bottom layers, and wall lines. BCN3D is implementing this measure to guarantee the optimal printing experience with Omega and to prevent users from making adjustments that might compromise their printing results. However, those customers that would like to experiment with print profiles, will be able to do so through the OOFL. By unlocking this, customers will be able to tailor print performance with BCN3D Filaments, Open Filament Network (OFN) Filaments and Third-Party Filaments, by customizing any print setting needed in BCN3D Stratos.

2. Print with third-party filaments: This license will unlock Omega to print with third-party filaments, offering the customers the flexibility to use custom materials and create their own printing profiles.

For more information: https://3d.bcn3d.com/bcn3d-omega-i60-omega-open-filament-license

-

- Which are the current and expected filaments for Omega BCN3D Filaments?

Available

· Omega Proto is the top choice for functional prototyping, producing precise parts with an ultra-premium surface finish. Omega Proto stands out for its exceptional versatility, providing remarkable durability, toughness, and chemical resistance. It surpasses PLA in strength, is more user-friendly than ABS, and delivers a surface finish superior to PETG. On top of that, Omega Proto offers great layer adhesion, creating stronger bonds between layers than what is achievable with typical prototyping materials.

· Omega Resistant Nylon is a custom copolymer of PA6 and PPA formulated especially for Omega I60 and designed for the most demanding manufacturing applications. This innovative material boasts exceptional resistance to chemicals, wear, and solvents, making it ideal for challenging environments. With superior heat deflection properties and printability surpassing traditional ABS and nylons, Omega Resistant Nylon sets a new standard for durability and performance in industrial settings. In fact, in terms of mechanical properties, it’s closer to Ultem™ 9085 than it is to standard FFF Nylon-based materials.

· Omega Tooling CF is a carbon fiber-reinforced PA6 copolymer filament designed exclusively for use with the Omega I60 printer. This specialized filament boasts remarkable strength, durability, thermal stability, and stiffness —characteristics you’d expect from carbon fiber materials. It excels in high-temperature environments, boasting a high heat deflection temperature (HDT) of 177ºC.

· Omega Impact ABS is highly impact-resistant and offers excellent heat resistance up to 90°C, making it ideal for durable casings and technical parts. It boasts an excellent surface appearance and is food-safe, complying with EU 10/2011 and FDA 21 CFR standards. Also adhering to REACH and RoHS regulations, Omega Impact ABS is perfect for demanding professional use.

R&D stage

Support (OFN), Casting material (OFN), ABS-ESD (OFN), ASA (OFN), Omega Flex TPU 95A, Omega Tooling CF HT, Omega PPS HT, Omega Impact 74D

-

- Does the BCN3D Omega I60 include high-speed print profiles already?

High-speed FFF printing represents an exciting prospect emerging in the market, offering customers the potential for accelerated part production. BCN3D is committed to making this capability available in our new industrial offering. This capability depends not only on the printer’s hardware but also on slicer, firmware, and material capabilities.

Over the past year, BCN3D has successfully conducted tests of high-speed print profiles on the BCN3D Omega I60 3D Printer. BCN3D recognizes the importance of prioritizing quality and reliability over speed. As a result, we are taking a conservative approach and gradually introducing updates.

The first version of the high-speed print profile is available exclusively for Omega Proto filament. This profile is the first version of high-speed for Omega and works at a maximum of 150mm/s and 2000mm/s² acceleration. Version two of high-speed is scheduled for Q1 2025.

-

- Why is it necessary to have an active heated chamber?

A heated chamber facilitates the manufacturing of engineering polymers by maintaining an ideal temperature for the printable part throughout the printing process. This temperature control ensures the uniform construction of the part, minimizing the formation of internal stresses. Heating the chamber promotes relaxation and eliminates internal tensions during manufacturing, effectively preventing issues like warping and cracking. All of this ensures the best dimensional accuracy and mechanical durability for the printed part. The BCN3D Omega I60 heated chamber can reach temperatures of up to 70ºC (158 ºF), making it ideal for printing materials such as ASA, PA, ABS and reinforced PA, among others.

Wondering how the Omega I60 heated chamber performs over a print job? Check out this informative article.

-

- What is the function of the Material Operation System and what temperature can it reach?

This integrated material module offers a complete all-in-one experience. The MOS allows you to control not only the humidity, but also the temperature. This ensures that filaments are dried, which has a tremendous impact on both the print quality and on the mechanical performance of the printed part. BCN3D’s Omega I60 MOS can reach up to 70ºC (158 ºF) and provides an RH below 10%.

To get a better understanding about the MOS, check out the following article: Link

-

- Which motion system does Omega I60 use?

BCN3D Omega I60 utilizes a custom HAQ-XY Kinematics system. This motion architecture is considered one of the best systems for dual 3D printers and CNC machines, as it provides a lightweight, robust and precise approach. BCN3D Omega I60 equips an improved version of this kinematics by placing the pulleys in a slightly different position. As a result, the system experiences a significant reduction in twisting moments along the X axis during the printing process. These twisting moments are highly undesirable as they can have detrimental effects on the system’s performance and potentially lead to deformations in the X axis, thereby negatively impacting the quality of the printed parts.

-

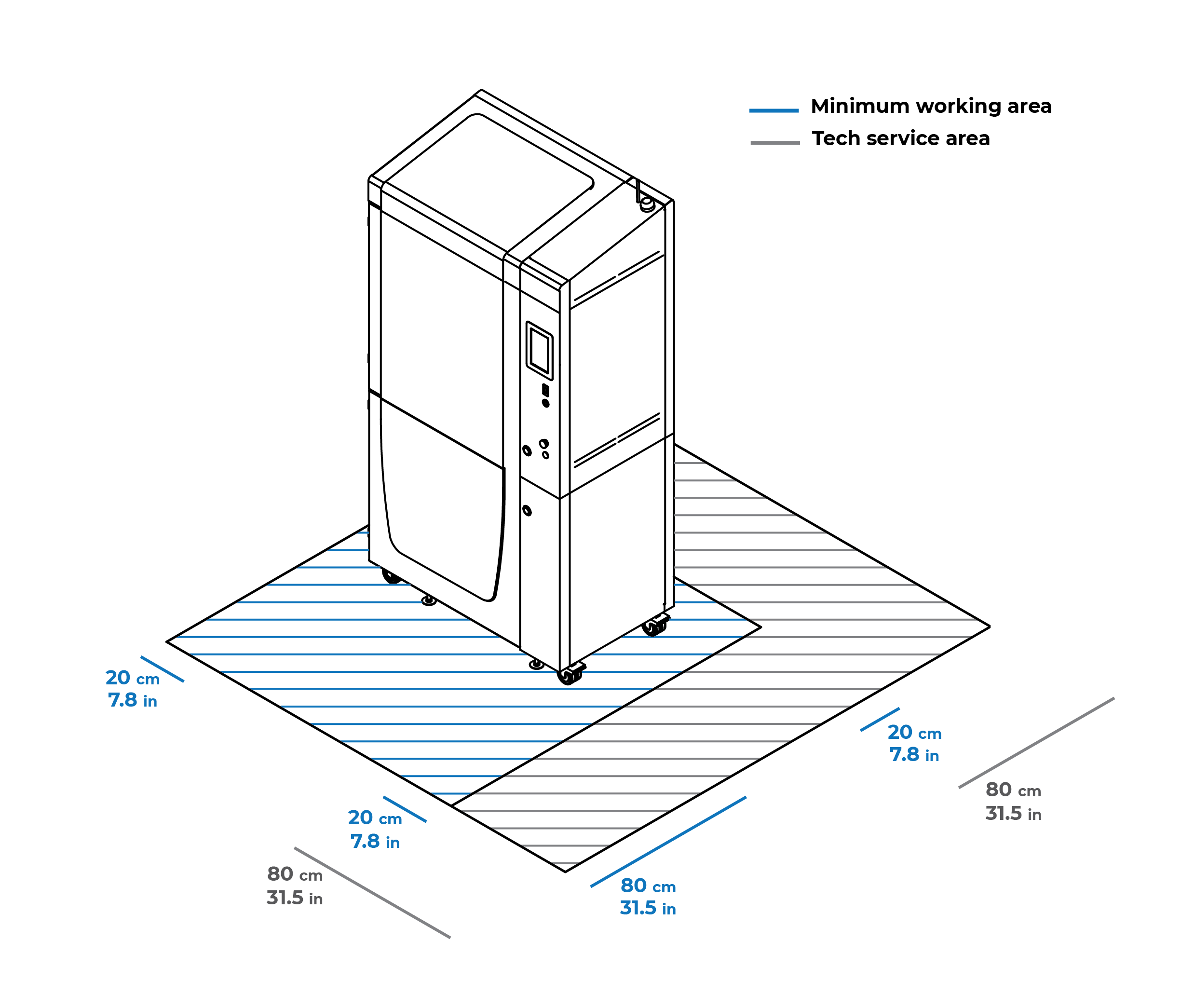

- Is there a minimum working area required for printer installation?

For printer operation: A minimum clearance of 20 cm (8”) is required on all sides of the printer, and except for the front, where a clearance of 80 cm (32”) is necessary to operate the printer.

For technical service: A minimum clearance of 80 cm (32 in) is required on all sides of the printer for accessing the front, right, and rear panels, except for the left side, where a 20 cm (8 in) clearance is sufficient.

-

- How to get a firsthand look at the BCN3D Omega I60?

Our distributors around the world have the Omega I60 in their physical showrooms and periodically exhibit the printer at relevant trade shows in their countries. Contact us at sales@bcn3d.com for more precise information.

If you would like to organize an online demo with our engineers, please fill out this form: Link

-

- Where can I find technical information, such as the User Guide, for the Omega I60?

Curious about how the new BCN3D Omega I60 operates? Explore the User Guide for detailed insights on unboxing, safety and compliance, printer setup, installation area recommendations, and more: Link

News

-

Success Stories

![The Epsilon W50 at Saint-Gobain]()

In-house 3D printed tooling brings an efficiency overhaul to Saint-Gobain’s production line

-

Blog

![]()

Introducing the New Generation of the BCN3D Epsilon Series: Optimized for superior performance

-

Press Release

![Viscous Lithography Manufacturing]()

BCN3D unveils Viscous Lithography Manufacturing (VLM)™, a new resin-based 3D printing technology to unlock manufacturing autonomy

-

Success Stories

![]()

Nissan is ahead of the curve with a dynamic implementation of 3D printed tools, jigs and fixtures in its assembly lines