3D Printing in Fashion: How Are 3D Printers Used In The Fashion Industry?

3D printing in fashion is gaining traction since designers and clothing producers discovered the benefits of 3D printing technology. They can use it to create fantastic 3D printed fashion with shapes and geometries never made before, but they can also prototype and it makes the clothing production process much more sustainable with 3D printed clothes.

Let’s dive into the world of 3D printing in fashion and see for yourself the different applications in the industry.

3D Printing in Fashion

Index

Currently, when it comes to 3D printed clothes, the practices are mostly limited to art pieces or haute couture for major fashion designers.

3D printing in fashion is an interesting avenue for designers and artists interested in creating complex geometric designs and wearable art. However, many of these designs are not really wearable in day-to-day life.

Although designers are innovating and developing new techniques, it is only on a mainstream level, 3D printed fashion is still growing. We expect to see this side of the fashion expand over the coming years.

Practical Uses of 3D Printers in Fashion

In a more day-to-day application, we use 3D printing in fashion to create accessories, build prototypes and manufacturing tools, boost sustainability efforts, and expand customization options.

3D Printed Fashion Accessories

Instead of 3D printing full items of clothing, 3D printers in fashion are used to supplement parts of a whole design, like embellishments, accessories, and buttons.

Small end-use accessories can be easily assembled in just minutes using 3D printing. Such materials with a flexible nature, as TPU, can be used to add accent pieces or unique embellishments onto the garment themselves. 3D printing is also helpful when creating costume jewelry with complex geometric shapes.

Prototyping and Tooling

Creating prototypes and tools for manufacturing are two of the most common uses of professional 3D printers, and the fashion industry is no exception to this.

Camper, a popular Spanish shoe company, uses BCN3D printers to build prototypes and concept models for each new shoe collection they create. Previously, they used to outsource the production of these models, adding more costs and time to the overall design process. Now, with several 3D printers in-house, their designers can get a much better understanding of the volumes and shapes of their designs.

3D printers also encourage designers to take more design risks, since they can quickly assess the viability of their designs. Prototyping different design iterations in this way allow designers more time and freedom to come up with new innovative designs.

3D printers are practical to create tools that will help in the manufacturing of the final garment or accessory. For example, Louis Vuitton, a prominent high fashion company, uses 3D printing to produce tools that help ensure that their final products are produced efficiently yet elegantly.

Sustainability

3D printing technology in the fashion space is also gaining traction for sustainable fashion, as more designers and brands are beginning to seek sustainable methods to create their collections.

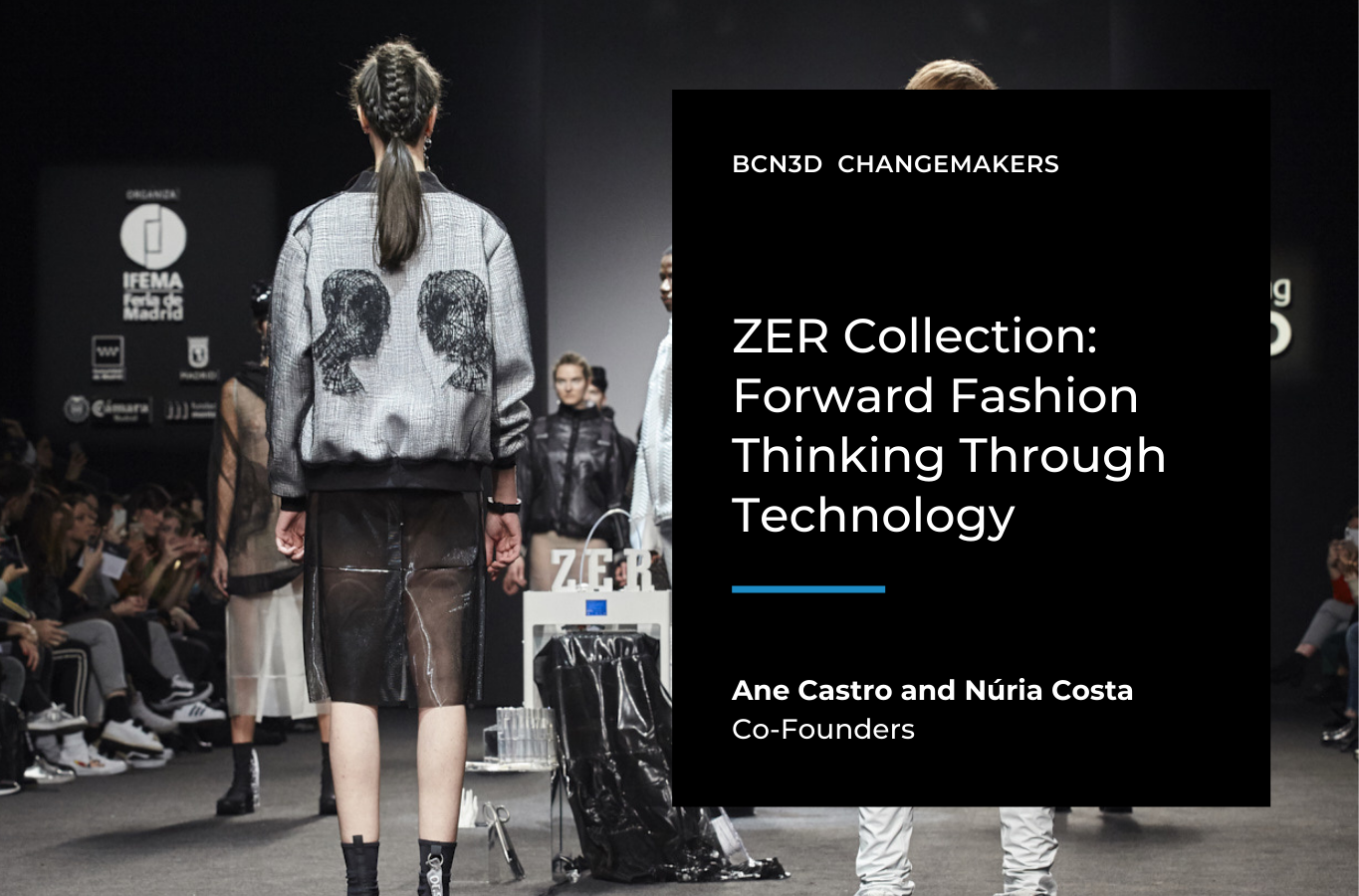

A great example of this is the innovative Spanish fashion brand ZER. They use additive manufacturing throughout their designing and creation process as a means to be a sustainable force in the fashion industry.

They use 3D printers to design their specific patterns and then print only the amount of product needed. This allows them to cut back on wasting resources for each garment, and ensuring that their manufacturing process is not harmful to the environment.

3D printers benefit sustainable fashion efforts thanks to the reuse and recycling of materials to create new designs. This is also an effort that ZER is making and one that could be interesting for many different brands looking to increase their sustainability efforts.

Customization

Finally, 3d printing in fashion opens the doors to new possibilities when it comes to customization options. Brands can begin to fabricate pieces based on the consumer’s specific needs or body parts.

The German sportswear company Adidas has been experimenting with this concept since 2015. Using running data from athletes, they have created a shoe that provides the optimal fit for any runner. They continue to experiment with different iterations of this 3D printed shoe today.

Conclusion

In conclusion, from end-use designs to behind-the-scenes processes, 3D printing is establishing its presence and benefits in the fashion industry. It will be exciting to watch the innovations, tactics, and designs that are created as this technology grows.