7 Useful 3D Printed Tools To Make Today [2020]

3D printing is commonly used in the manufacturing industry to create useful 3D printed tools, like fixtures, jigs, and parts that help speed or ease the manufacturing process.

In-house 3D printers are a huge asset on any production floor, and there is an endless amount of things you can make with a 3D printer. Whether it is rapid prototyping, fixing broken production parts, or creating a tool that will help speed up a previously tedious process, 3D printed tools are a major benefit for manufacturers.

Let’s review 7 useful 3D printed tools that you can create to help ease the manufacturing process.

7 Tools You Can Make with a 3D Printer

1. Custom Tools

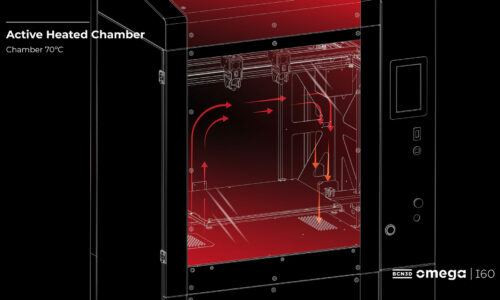

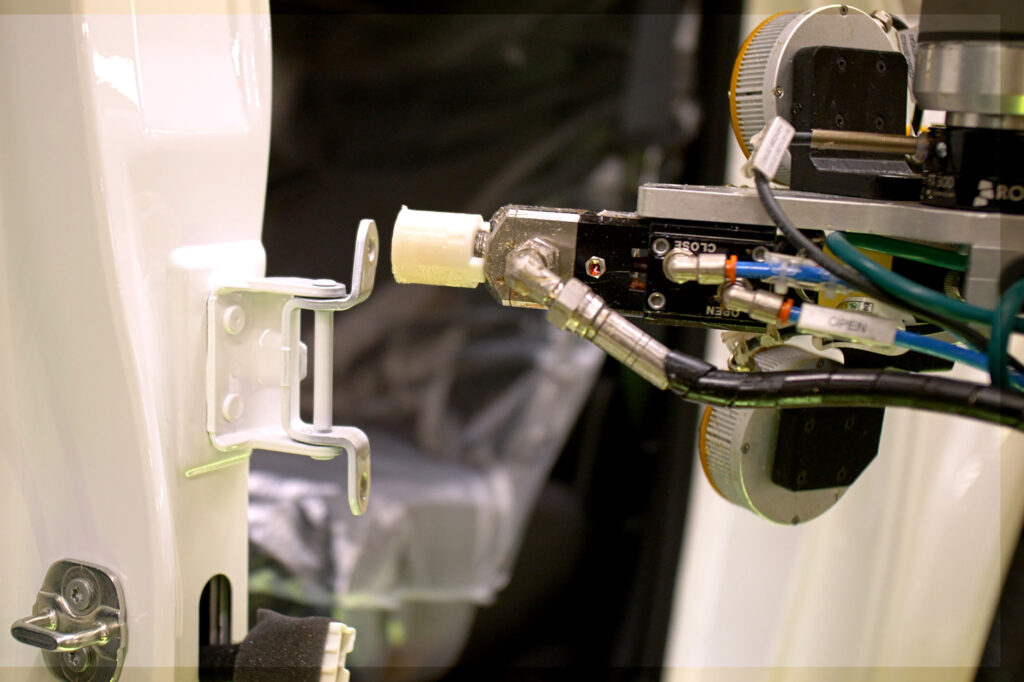

By far the largest benefit that 3D printers bring to the manufacturing industry is the ability to create custom 3D printed tools for any production or assembly needs. 3D printed tools can be created for machining, assembly, molding, casting, or even as robotic parts along an assembly or production line.

When manufacturers require custom tooling, the process is often lengthy and expensive, and usually involves relying on an outside producer. With an in-house 3D printer, custom tools can be created in a matter of hours or days instead of weeks. Not only does this cut down on time and production limitations, but it also cuts costs for the manufacturers.

3D printers also provide the opportunity to create multiple iterations of the tool with as much customization as needed. Typically 3D printed tools are more lightweight than traditional metal tools. Also, if tooling is needed for an individual, like a shield, mask, or tool with a grip, it can be customized to the person who will be using it.

Custom tooling opens the doors for faster production, flexibility in the manufacturing process, and reduced costs.

2. Jigs & Fixtures

Jigs and fixtures are another key 3D printed tool that manufacturers often rely on. Thanks to the custom nature of jigs and fixtures, having a 3D printer on hand to create these tools is invaluable and is truly a game-changer in terms of cost and speed.

3D printed jigs and fixtures can aid in the assembly process by quickly designing and printing the needed parts in a way that is much faster than traditional production. Even better, jigs and fixtures can be created multiple times to ensure that they work well for their specific needs. The creation of jigs and fixtures is perhaps one of the biggest benefits of 3D printing in the manufacturing industry.

3. Handles

Broken or cracked handles can be a common issue on any factory floor. Rather than tossing and replacing a perfectly good tool, manufacturers can use an in-house 3D printer to create a custom handle in a matter of minutes or hours. Handles can easily be created for tools like a hacksaw, knife, razor scraper, screwdriver, mallet, and more. Additionally, you can also use the 3D printer to create handle modifications or make a more ergonomic custom handle.

4. Injection Molds

3D printers can also be used to create molds for injection molding. Traditionally, metals are used to create molds or frames, but with 3D printers manufacturers have more design freedom and shorter waiting times to create these pieces. All3DP claims that 3D printed injection molds can even save “up to 80% of costs compared to conventional techniques.”

3D printed injection molds are significantly cheaper and quicker to make than traditional molds using CNC machinery. It is important to choose 3D printing materials that are both stiff and heat resistant, as they will need to be able to withstand high heat and pressure. 3D printed injection molds are especially useful if you only need low to medium amounts of batches.

5. Saw Guide

If you are creating unique shapes, a 3D printed saw guide can help ensure you stay on the right track. This 3D printed tool is highly customizable to whatever final product you are making. If you use strong filaments, your design will be able to stand the test against the saw. This 3D printed tool highlights the flexibility and ease of design that 3D printers allow manufacturers.

6. Sanding Stick

While there are many different sanding tools on the market, sometimes manufacturers have to get into hard-to-reach places that typical tools just can’t reach. A 3D printed sanding stick allows producers to easily get into those nooks and crannies and sand down any small pieces. This 3D printed tool is easy to make and solves a common headache in manufacturing.

7. Finger Wench

Speaking of hard-to-reach places, a 3D printed finger wench is also a crucial and easy-to-make 3D printed tool that can be a life-saver. This tool can be easily made on the factory floor in a matter of minutes, allowing you to screw down pieces in tight corners or small spaces.

Conclusion

When it comes to the list of what you can make with a 3D printer we’ve only just scratched the surface, especially when it comes to manufacturing. The biggest benefit of 3D printed tools in the manufacturing and production industry is customization. The ability to customize your 3D tools into whatever needs you have is what makes 3D printers on the factory floor so valuable.