IDEX Technology: Doubling Productivity While Halving Costs

Independent Dual Extrusion technology (IDEX) enables 3D printers to work with both tool heads simultaneously and independently, resulting in countless benefits. This white paper will give you an understanding of how IDEX technology works, how it came to life, and its main differences compared to single and dual extrusion.

How did IDEX come to be?

How did IDEX come to be?

In 2014, when we realized that a dual extruder over the same tool head still caused some inconveniences, we knew there was room for improvement.

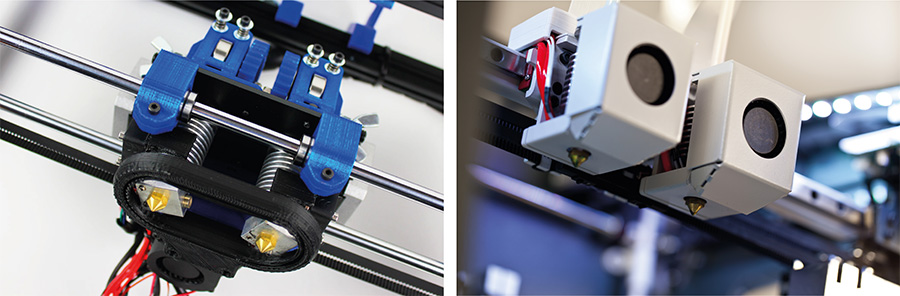

This sparked the idea of trying to develop a form of independent dual extrusion. The first trial turned out to significantly ease the process of calibrating the extruders, preventing filament dripping from the idle extruder on the piece being printed and providing more flexibility when printing different materials.

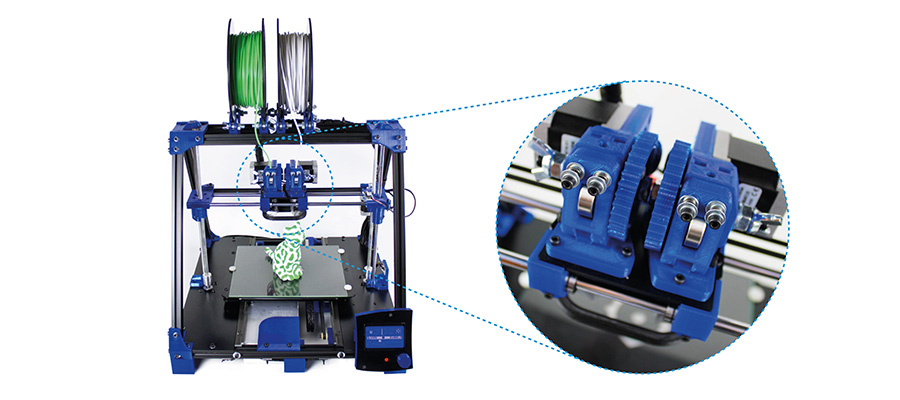

A complete independent dual extrusion solution was introduced in 2015 with the BCN3D Sigma.

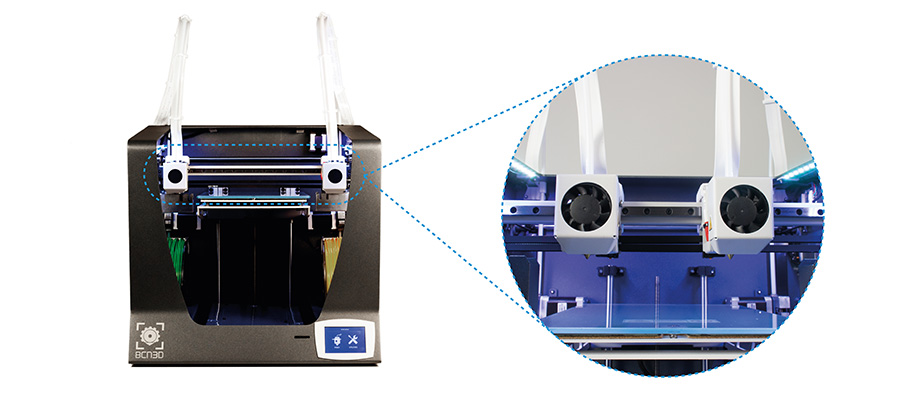

With the launch of the BCN3D Sigmax in 2018, came the Duplication and Mirror 3D printing modes; unique features of 3D printers and key in the high productivity provided by the BCN3D printing solutions.

How does IDEX technology work?

Conventional dual extruder 3D printers usually have a series of mechanical axes:

- X, Y, and Z position the tool head and the piece that is being printed spatially

- E is responsible for the progress of the filament in the extruder

IDEX technology allows for these axes to be doubled. Therefore, a 3D printer equipped with this technology has X0, X1, Z, E0, and E1 axes as well. This essentially means that the printer keeps sharing the Y and Z axes, while both extruders have their own X and E axes, making it possible to print with two tool heads independently.

The benefits of IDEX technology

IDEX allows users to print more complex pieces by using hydrosoluble supports, and to combine materials to obtain different mechanical properties in one single print. Two different colours can be used, and different nozzle sizes can be combined for more resistant parts and to save time.

Furthermore, the two extruders are controlled independently, which prevents cross-contamination.

This system reduces the cost of machinery in half, as, with the same number of 3D printers, the final customer can get twice as many printed parts as they would get with other dual extrusion machines, thanks to BCN3D’s signature Duplication- and Mirror modes.

There is no doubt that IDEX technology is the most cost-effective and fastest solution for production. Don’t forget to download our white paper, where you will find more information about this technology and several practical examples of how our customers use their independent extrusion systems on a daily basis.

BCN3D was the pioneer of IDEX technology, revolutionizing the 3D printing industry by offering many customers worldwide an easy and effective way of doubling productivity while keeping costs low. Could IDEX do the same for you? Reach out today!