The causes of brittle PLA filament and the easy steps to overcome it

We take a look at the indicators of brittle PLA filament, the reasons why, and the solutions for this issue. We also discuss the variety of applications you can explore once you’ve got your PLA printing in tip-top condition.

Looking for the secret to solving brittle PLA filament? We keep you in suspense any longer…if you’re experiencing this problem, it all comes down to storing this material correctly. Let’s dive into how to spot this issue early on, how to solve it, and the suitable applications for this 3D printing material.

Symptoms of a damaged material

The following indicators point to a damaged spool:

- The material surface isn’t smooth and you can see tiny bubbles

- You’re experiencing underextrusion while printing

- The material continues to ooze out, even after the extruder motor has stopped pushing it through the hotend

- You can hear sizzling/popping noises coming from the nozzle while the filament is being extruded

Smart storage

All of these issues that contribute to brittle PLA filament come down to 3D printing’s number one enemy: humidity. As soon as you open your filament spool, the first thing on your mind should be protecting the material from any damage.

To guarantee the best print quality, it is crucially important to keep your materials in a sealed, humidity-controlled environment. The optimal conditions for storing your filaments, in general, are in a dry, cool place with a resealable bag, avoiding direct sunlight; for PLA, 45ºC for 6 hours before printing.

Of course, you always have the BCN3D Smart Cabinet as an option. Our smart drying technology works on the absorption dryer method, using alumina-based pellets as a desiccant and alternating between drying cycles and regeneration cycles to maintain a constant dry environment around the stored spools and protect them from sudden external changes.

How do you restore brittle PLA filament?

When a material is damaged or degraded by humidity, it now holds moisture on its surface or deep within its matrix. This cannot be reversed by the BCN3D Smart Cabinet and so we have to look elsewhere for a solution. It’s possible to use a regular, preheated oven or food dehydrator to dry out the filament, as long as the damage isn’t too far gone. For PLA, we recommend no more than 45ºC to avoid further damage.

Suitable applications for PLA

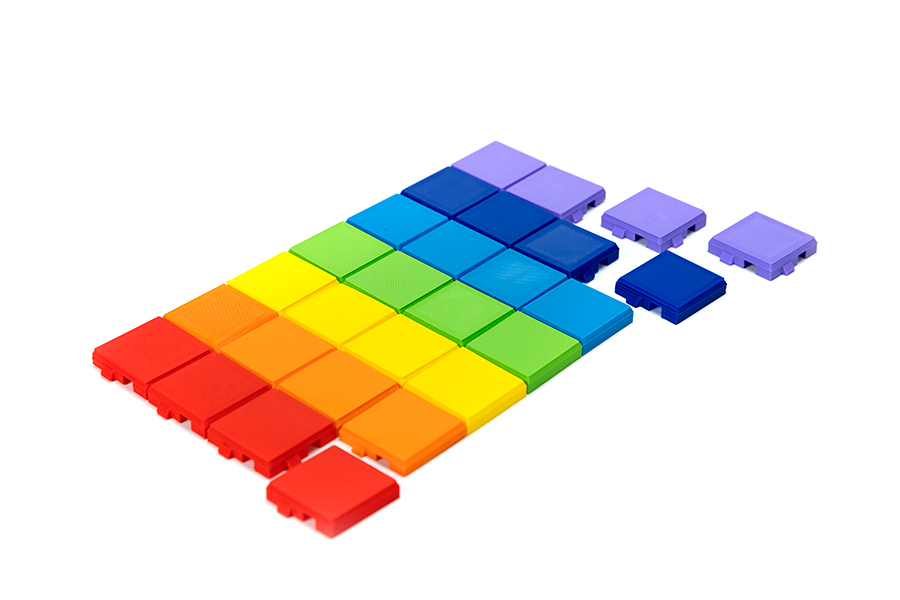

Mix and match colors and materials

PLA comes in a wide variety of colors and is the perfect material to pair with soluble supports for printing parts with overhangs, complex geometries, and intricate curves. These dual color/material prints are easily achievable with the use of IDEX technology.

Prototyping heaven

PLA is easy to print, and ideal for models and prototypes that require a good surface quality and aesthetic detail.

Affordable concept design

Since it’s a cheap material, PLA can be incorporated into the process of developing the conceptual design of a product to drastically reduce the costs of product development and allow the evaluation of the part’s functionality.

In a nutshell, PLA is most commonly used for applications such as:

- Architectural mockups

- Aesthetic, concept models

- Investment casting molds

- Low mechanically demanding prototypes

To sum up our advice for brittle PLA filament:

- Remember the magic formula for PLA preparation: 45ºC for 6 hours

- Smart storage is key

- Restoring is fairly straightforward using heat

- A well-printed PLA provides a variety of applications

For even information on the effects of humidity on other 3D printing materials, consult this specialized article created by the brainiacs that make up the BCN3D support team.