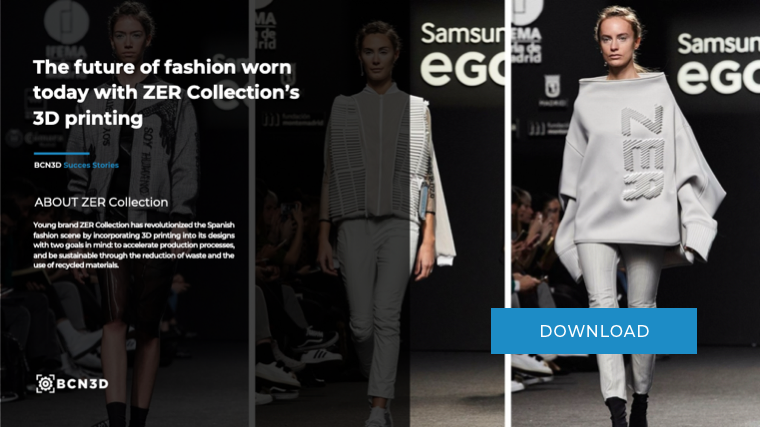

The future of fashion worn today with ZER Collection’s 3D printing

Young brand ZER Collection has revolutionized the Spanish fashion scene by incorporating 3D printing into its designs with two goals in mind: to accelerate production processes, and be more sustainable through the reduction of waste and the use of recycled materials.

Barcelona, 9th January 2020-. Born in 2017, Spanish fashion brand ZER Collection focuses on designing “futuristic, functional and urban clothing with sporty aesthetics”. Its first collection was introduced with great success during the last Mercedes Benz Madrid Fashion Week, and included 12 outfits with the majority of their parts 3D printed.

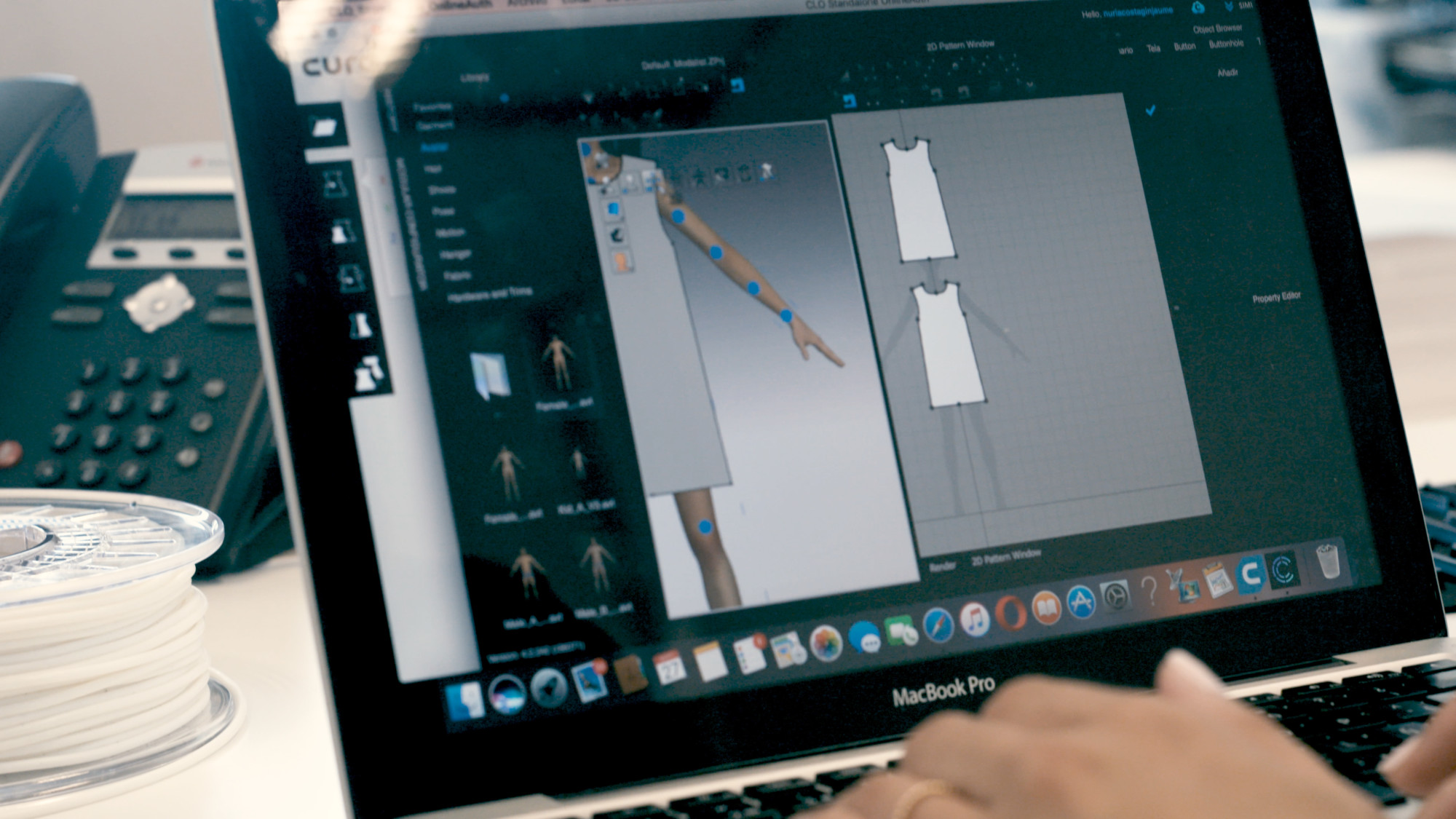

Ever since the brand began, co-founders and designers Núria Costa and Ane Castro have been working to contribute to the introduction of new technologies in the apparel industry. In their exploration of new opportunities in sustainable manufacturing practices, they discovered 3D printing and never looked back.

Life in the fast lane

A significant advantage of additive manufacturing, in this case, is the considerable acceleration of their processes, thanks to the IDEX technology in their BCN3D Sigma 3D printer. “We work much faster, because we can print two fabrics at the same time”, assures Costa, while Ane Castro highlights that this system enables them to combine two different materials with different properties, such as elasticities and thicknesses.

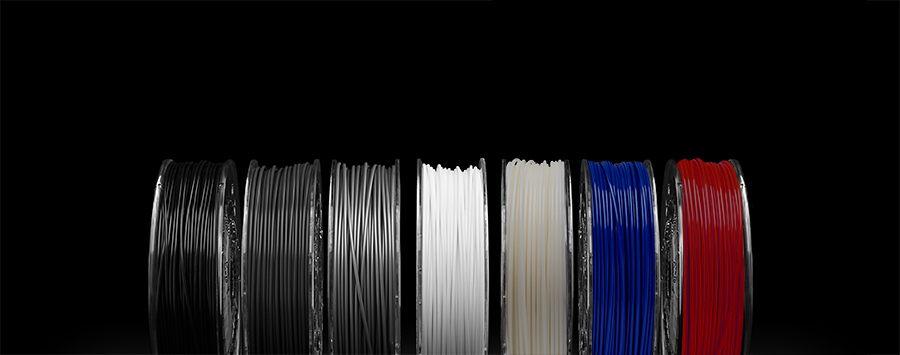

3D printing offers them many possibilities to create innovative designs, while working with flexible materials such as TPU, and guarantees the functionality of all garments, which is an absolute must in their collections.

A sustainable new era of fashion

In addition to the innovation that using 3D printing in fashion represents, and to its production benefits, this technology can also contribute to boosting the sustainability of the fashion industry as a whole. In the case of ZER Collection, its founders have started a line of research in which they “create tissues without generating any residue, tissues that are also biodegradable and have a closed life cycle”.

Núria Costa says they can now “digitize all patterns in order to produce only the necessary fabric”. During the cutting process of most of the apparel worn, Costa explains, “normally up to 30% of the fabric goes to waste”. Using a 3D printer means that they produce “only the fabric needed for each garment”, reducing the amount of waste to almost zero.

Their whole process, from design to end-use, is focused on sustainability, so ZER Collection also recycles the materials from used garments, melting the plastics into a once-again printable filament and re-using it for new items.

For Castro and Costa, there’s no doubt that 3D printing “opens a range of possibilities within fabric design, providing them with functionalities that cannot be achieved without the use of this technology, from an elasticity that we can control and modify depending on our needs, to protection against different impacts. We believe that the use of 3D printing represents a revolution in fashion, in environmental care and in society”.

3D printing and IDEX technology have therefore a huge impact on the workflow of the team at ZER Collection, and have allowed them to work towards their goal of complete sustainability. ZER Collection continues to stay on top of new technologies and techniques, improving sustainability and creativity as a result.