Storing and drying your filaments for optimal results

This whitepaper explores the detrimental effects of humidity on polymers and compares traditional 3D printing filament drying methods to the effectiveness of the BCN3D Smart Cabinet.

Depending on geographical factors and the weather, water can make up as much as 2% of the volume of the air that we breathe. This is where 3D printing’s enemy comes in; hygroscopicity is the tendency of a solid substance to absorb moisture and a prominent characteristic of almost all thermoplastic materials.

Hygroscopicity explained

While non-hygroscopic materials tend to only absorb water on their surface, which can be removed by simple heating, polymeric materials can absorb large quantities of humidity from the air and store it deep within their matrix. This means they must be stored correctly in the right environment or subjected to dehydration. The most common 3D printing filaments are formulated with hygroscopic materials, such as PA, TPU, PVA, PET-G, or ABS.

Our research into humidity

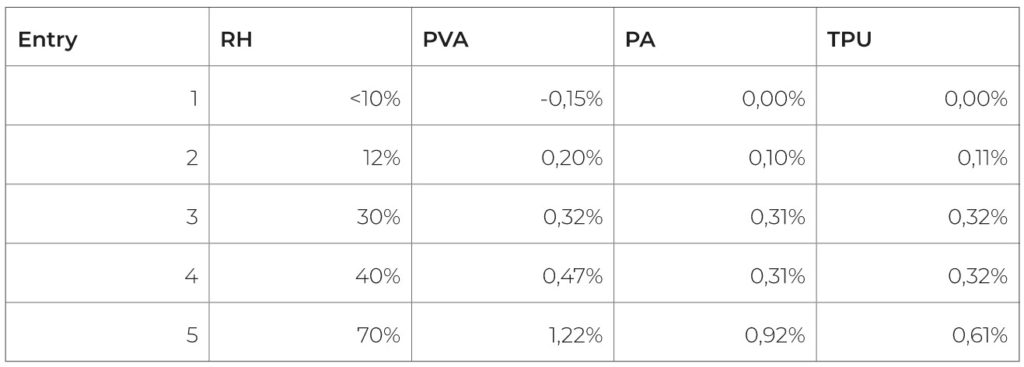

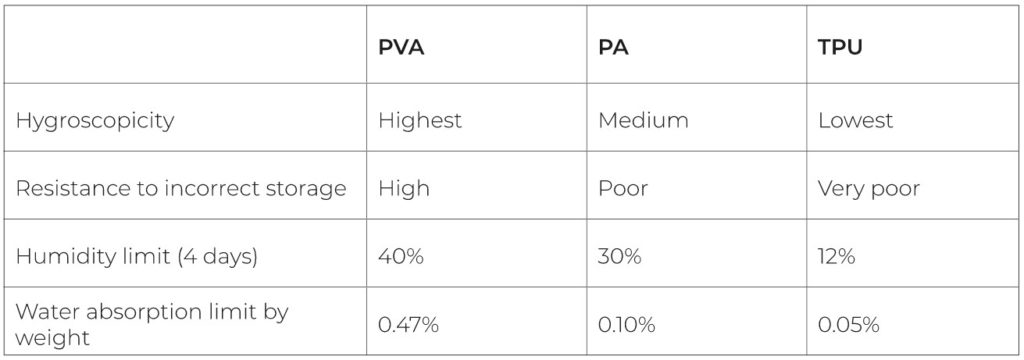

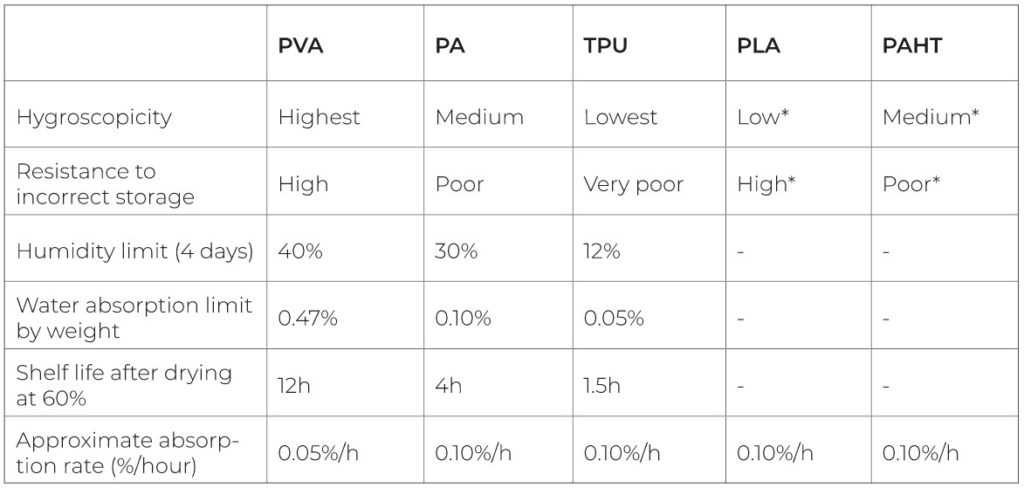

We set out to research how the absorption of water occurs in each material and how their performance is affected. We found that the most hygroscopic materials are PA, PVA, and TPU. Here you can see the amount of water these 3D printing spools absorbed.

TPU, which is the least hygroscopic out of these three materials, is also the most sensitive to incorrect storage.

We then looked into the effect of time on the rate of water absorption of different materials. These numbers are quite alarming and show how easily humidity and incorrect storage can affect the outcome and consistency of the FFF 3D printing process.

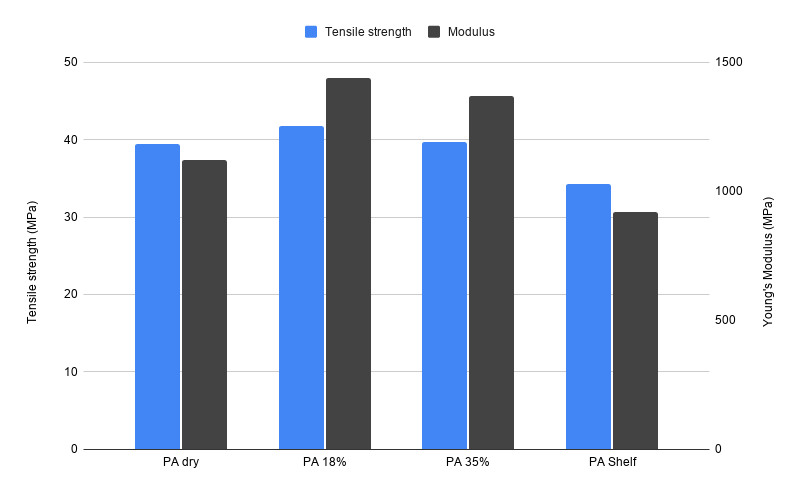

For our third test, we measured the tensile behaviour of hygroscopic PA by removing all moisture from 4 spools and then storing them in different humidity conditions. The results showed a detrimental effect on water’s mechanical properties of tensile strength and Young’s modulus.

To read more about the experiments conducted by the BCN3D Engineering team, download the white paper here!

Different ways of drying

Our whitepaper contains a detailed comparison of traditional and professional drying methods. There are a number of traditional drying methods, such as oven baking, air conditioner or dehumidifier, desiccants. However, professional drying methods, such as adsorption dryers, hot air drying process, vacuum process and the BCN3D Smart Cabinet, achieve significantly better results.

Results with the BCN3D Smart Cabinet

The BCN3D Smart Cabinet works by the silica gel inside, open to the dehumidifying environment, absorbing the moisture from the air in the chamber. Once it becomes saturated, the gel is isolated from the materials and heats up until it releases the moisture, purging it out of the system. Afterwards, the gel is refreshed and ready to collect more moisture.

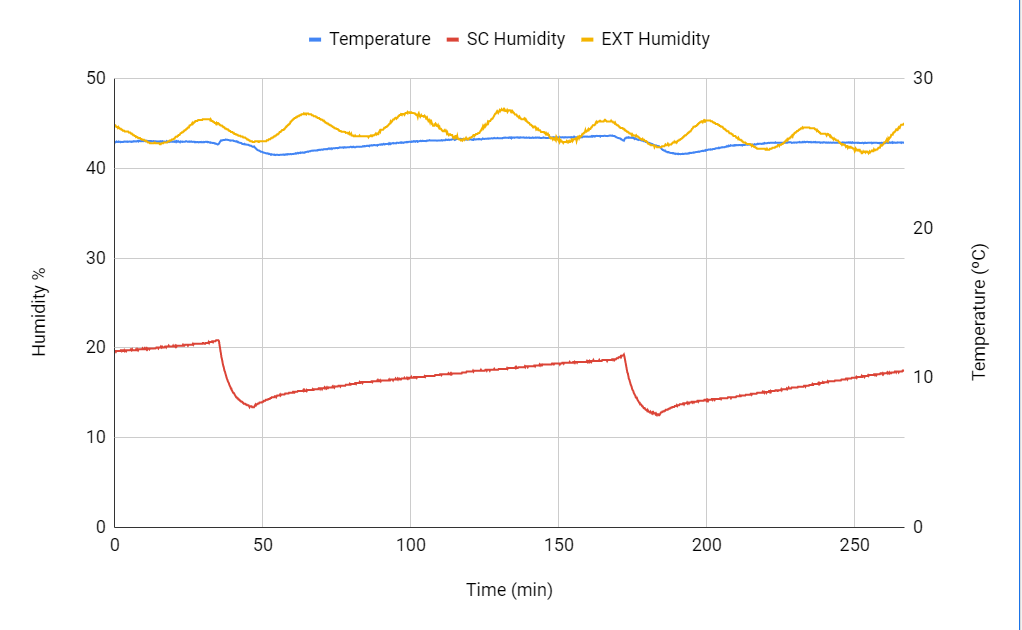

As shown in the graph below, even with an external humidity of 55%, the Smart Cabinet ensures an internal humidity rate between 15-20%, to preserve filaments’ printability, extend their shelf life, and to reduce aesthetic defects on end results.

The BCN3D Smart Cabinet has a low energy consumption (12 W Avg / 100 W Max.), while keeping the filament below the 40% relative humidity rate. It can dry up to 8 small spools of filament (between 750g to 1 kilogram), or 4 big spools (up to 2,7 kilograms per spool), without heat, therefore maintaining the materials’ tensile strengths.

It is crucially important to keep materials in a sealed, humidity controlled environment. This is where our BCN3D Smart Cabinet comes in handy, extending service life of materials, providing optimal conditions even during printing and excellent results.

Interested in discovering the other members of the BCN3D Epsilon ecosystem? Get to know more!