Precision Grinding and Erosion Leader Vollmer of America Innovates with Specialized, Cost-Effective 3D Printed Tooling

Vollmer of America, a leader in precision grinding and erosion machines, has transformed its operations by integrating additive manufacturing technology using BCN3D Epsilon printers. This has allowed the Pittsburgh-based company to swiftly create custom tools and prototypes, effectively addressing challenges such as developing specialized tools for service engineers and designing protective holders for expensive grinding wheels in smart cabinets. The adoption of 3D printing has improved efficiency, reduced costs, and reinforced Vollmer’s commitment to innovation and excellence in the industry.

Founded in 1909, Vollmer Group has established itself as a global leader in state-of-the-art grinding, erosion, and processing machines for the wood and metal industries. The company is renowned for its commitment to quality, precision, and innovation, serving a diverse range of customers, including sharpening services, saw mills, and tool manufacturers. With over 800 employees worldwide, with around 550 of these at the main headquarters in Biberach (Germany) alone, and a strong focus on research and development, Vollmer continuously strives to maintain its position at the forefront of technological advancements.

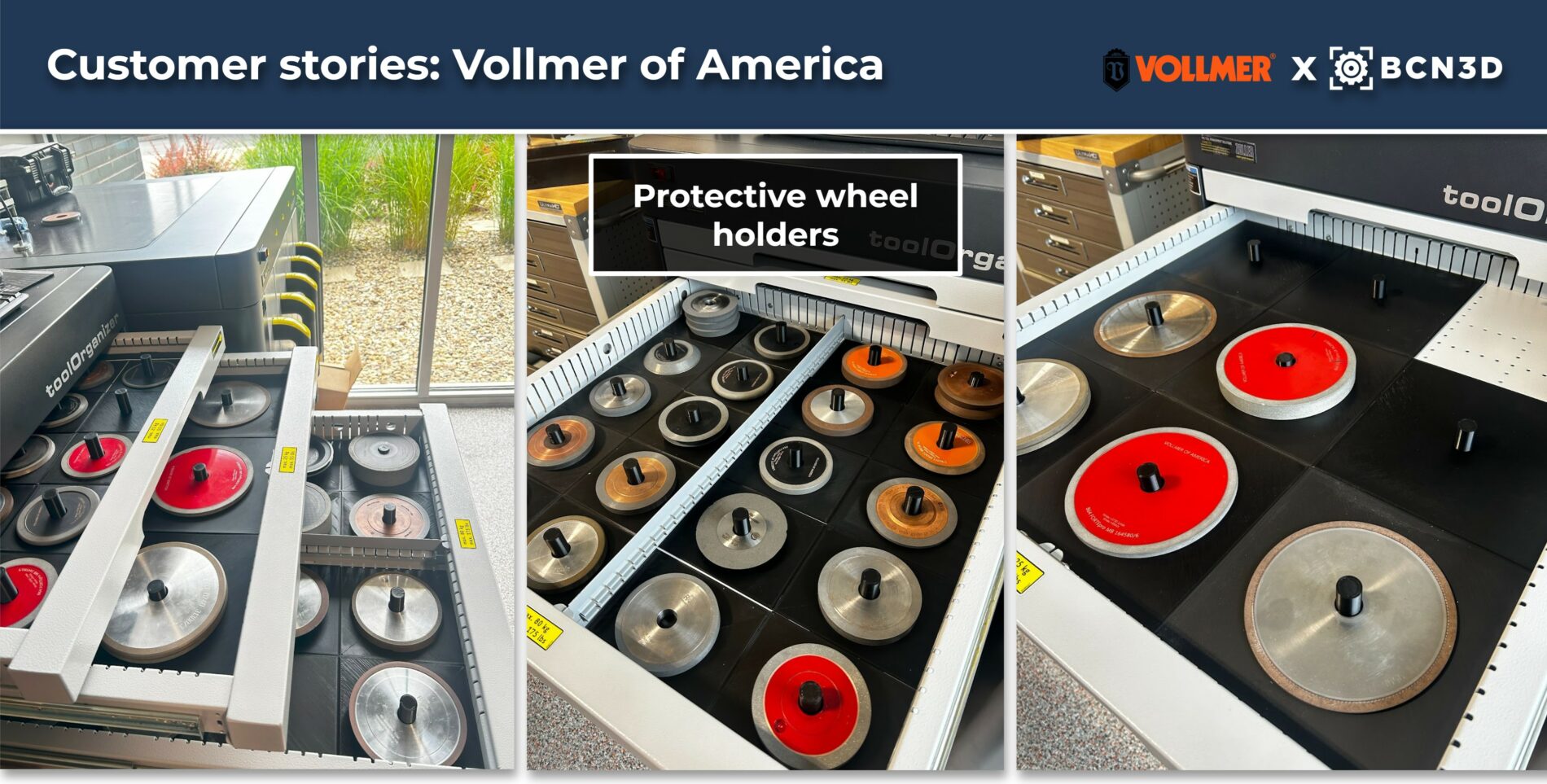

At one of its subsidiaries, Vollmer of America, the integration of 3D printing technology has proven to be a game-changer in their operations. Derrick Bailey and Carlos Becerra, Applications Engineers for Rotary Tooling, have spearheaded this transformation, driven by the need for rapid prototyping and the creation of custom tools. “We needed quick, cost-effective solutions to address specific challenges our service engineers faced, such as removing caps from mixing valves and preventing damage to expensive wheels in our smart cabinets,” explains Derrick. Traditional methods, while effective, were either too slow or incurred high costs, prompting Vollmer to explore the capabilities of 3D printing.

The introduction of BCN3D Epsilons has provided Vollmer with significant advantages. “The ability to produce prototypes and fixtures almost instantly has revolutionized our workflow,” says Carlos. The printers’ dual extrusion capability, fully enclosed design, and humidity control were key factors in their selection, ensuring that each print meets the high standards of precision and reliability that Vollmer is known for.

The ability to rapidly iterate and refine prototypes has accelerated Vollmer’s innovation process, allowing them to respond to customer needs with greater agility. “3D printing has fundamentally changed how we approach problem-solving,” Derrick adds. “We can now bring our ideas to life in a matter of days, not weeks. I would highly recommend BCN3D printers to any company looking to enhance their production capabilities and streamline their operations.”

Moreover, 3D printing has enabled Vollmer to solve multiple operational challenges efficiently. For instance, when off-the-shelf tools failed to meet their needs, the team quickly designed and printed custom tools at a fraction of the cost and time compared to traditional outsourcing. This flexibility has also extended to the development of protective solutions for sensitive components, such as custom holders for wheels in smart cabinets, preventing damage and ensuring easy access.

Beyond prototyping and custom tools, Vollmer has also explored the potential of advanced materials like Hotend X and PAHT CF15 in their 3D printing processes. Although still in the testing phase, these materials offer promising results in terms of strength and heat resistance, making them suitable for more demanding applications. “We’ve only just begun to tap into the capabilities of these materials, but we’re already seeing the potential for even more robust and durable parts,” Derrick adds.

Through the strategic implementation of 3D printing, Vollmer of America continues to uphold its tradition of excellence while embracing new technologies that drive efficiency and innovation across its global operations.