Introduction to FFF technology and its most important parameters

Discover in this article the basics of FFF technology, and find out which the most important parameters are when it comes to 3D printing.

About Fused Filament Fabrication Technology (FFF)

Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), is an additive manufacturing process that deposits a thermoplastic material layer-by-layer in order to build a part. FFF technology manufactures strong, durable and dimensionally stable objects with an unmatched accuracy.

Among the multiple 3D Printing technologies in the market, FFF is the most widely spread. The main reason for this is that both the hardware and material are affordable, requiring a low initial investment compared to other technologies. Secondly, there is a large range of materials available, so the technology is suitable for multiple applications and markets. Finally, the design criteria needed and equipment operation are simple enough, especially compared with other 3D Printing technologies, so there is no need for specialized operators or complex training.

The technology supports industrial-grade thermoplastics such as Nylon, TPU, PET-G or ABS, among others. Check out our full portfolio of materials: BCN3D Filaments.

FFF’s most important parameters and its influence

Every 3D print starts with a digital design of an object, which is then divided in thin layers by a slicer software. The layer split is made in order to print in the XY plane and then give volume through the Z axis. When using BCN3D Printers, we recommend the usage of BCN3D Cura, a free and easy-to-use software entirely optimized for our printers.

When printing a digital design, the slicer is also required in order to select the material and the quality of the print. All the parameters described in this article are automatically calculated by BCN3D Cura, so the user doesn’t need to know any of them. Nevertheless, it is important to define them and know how they influence the quality of the part and its printing time.

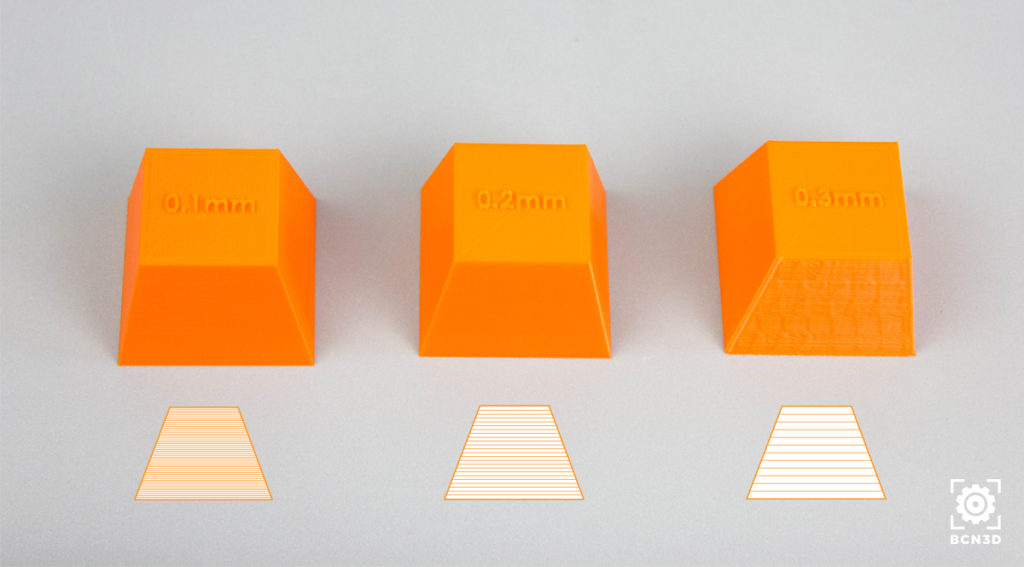

· LAYER HEIGHT

The layer height is an implicit parameter in all 3D printing processes. Geometries are generated in the XY plane and then extruded along the Z axis. This extrusion is made in layers, whose height can be modified through a slicer software to obtain the desired result.

Modifying layer height

There are two major factors that may influence when choosing layer height. First of all, the printing quality, since the layer height is equivalent to the vertical resolution of Z axis. Lower layer heights will result in smoother prints, because the number of layers will increase and so will the number of points that define Z axis.

The second factor is the printing speed, because when decreasing the layer height, the total number of layers is higher, and so is the printing time.

Therefore, for low values of layer height, the resulting part will be smoother but will also take more time to be printed; and thus, high values for layer height result in a loss of resolution, but faster prints. It is up to the designer to decide whether time or resolution is more important.

Normally, a part will be considered of high-quality when the layer height is below 0.15mm, and low quality when this value is above 0.3mm.

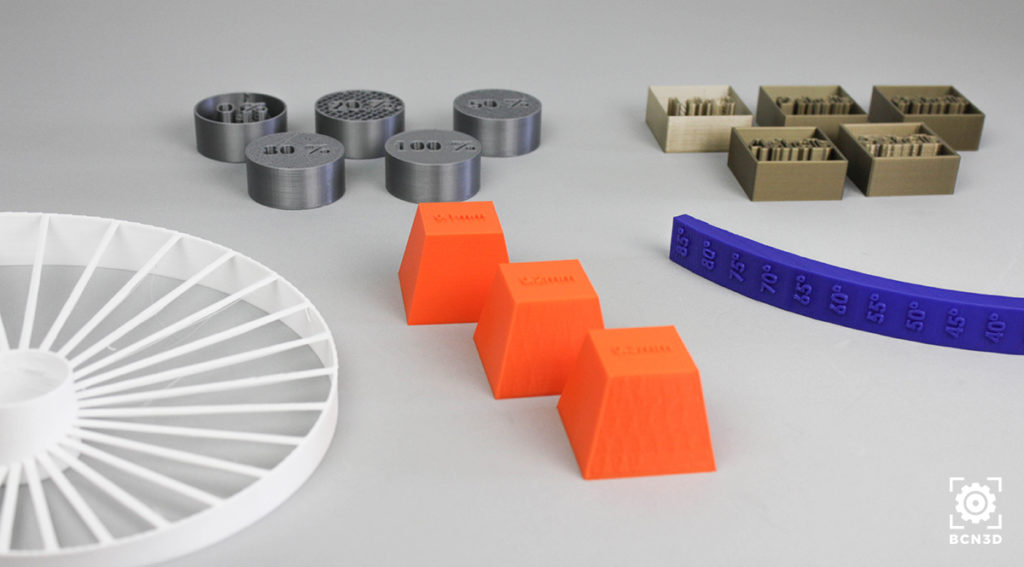

· INFILL AND SHELLS

When 3D printing with FFF technology, most of the parts are not printed completely solid. Printing a solid part means wasting a lot of material and spending a long time printing, and that means increased costs. Instead, these parts are filled with less material and wrapped with shells:

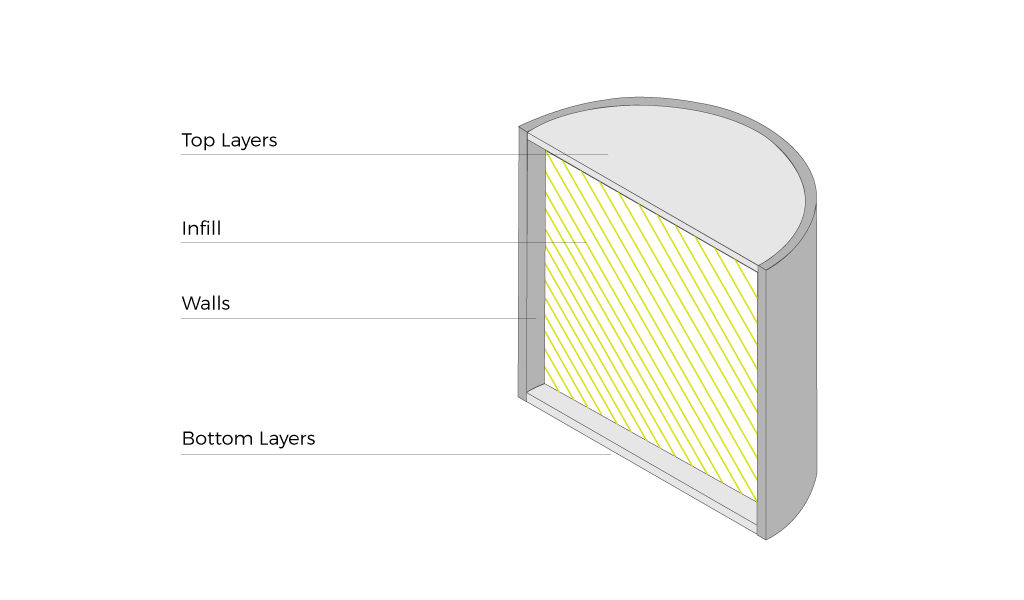

These shells can be broken down into different types depending on their position.

- Walls: the shells placed by the sides of the model.

- Bottom layers: the shells between the infill and the build plate. These are the first printed layers.

- Top layers: the shells between the infill and the nozzle. These are the last printed layers.

- Infill: the internal structure or skeleton of the part.

Modifying shells

Strength can be improved by adding shells, which will resulto in more printing time and more material used. The wall thickness is the value of the nozzle diameter, so the size of the wall must be a multiple of the diameter, to prevent voids between shells. The recommended number of shells in BCN3D Cura is 3, but it can be easily changed depending on the desired results.

Modifying infill

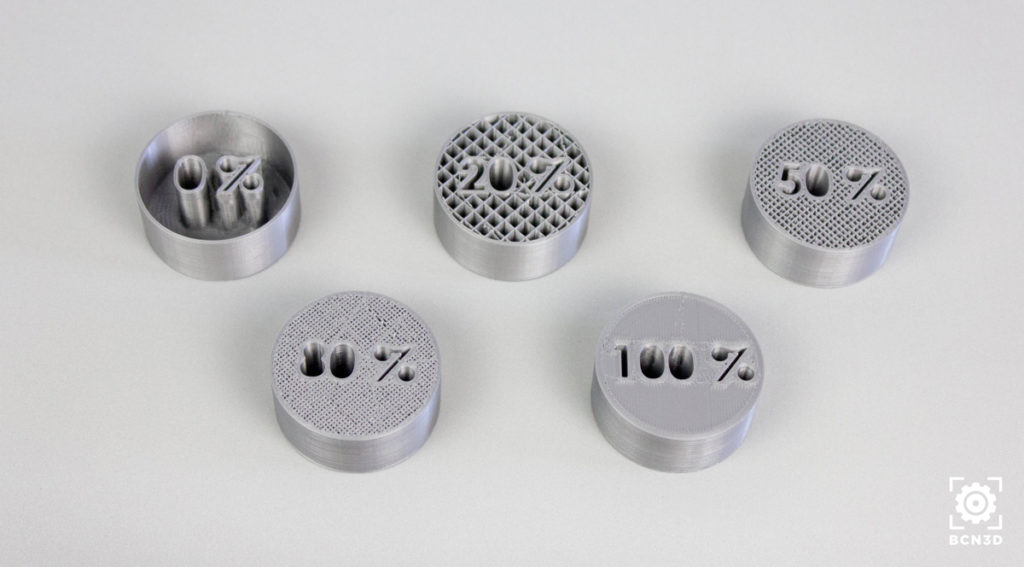

Infill is measured from 0% to 100%, being 0% a completely empty part and 100% a fully filled part. FFF parts are usually printed with a low value of infill, around 20%, in order to reduce time and material, but maintainig mechanical properties. When increasing the percentage, the strength of the design will also be increased.

So, when 3D printing a prototype, it would be enough with an infill of around 15%, whereas if it is a final part what we are 3D printing, the infill should be higher than 50% in order to ensure the necessary strength of the piece of its use.

· PRINTING SPEED

The speed at which the printing happens depends on the material, size of the nozzle, layer height, etc. It is a key factor to get the highest quality in printed parts: the highest the speed, the lower the final quality will be.

The printing speed has a remarkable influence on time. For small models, there won’t be much of a difference between slow and fast printing speed, but for large models it will seriously affect the total time the piece takes to be fully printed.

· TEMPERATURE

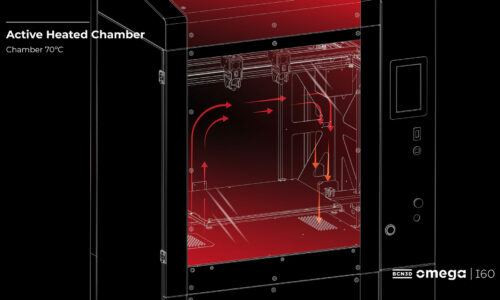

The printing temperature depends on the type and the quantity of material going through the nozzle. Each material has its theoretical melting point, but when 3D printing there is a different range of melting temperatures: the melting happens in the nozzle and it is instantaneous, which added to the presence of additives to improve the printing experience, cause the range temperature to be noticeably above the melting point of the material.

Modifying temperature

The optimal temperature is the lowest temperature that can melt the material completely. If the temperature is too low, the nozzle can have clogging issues because of the non-melted material.

· OVERHANGS AND BRIDGING

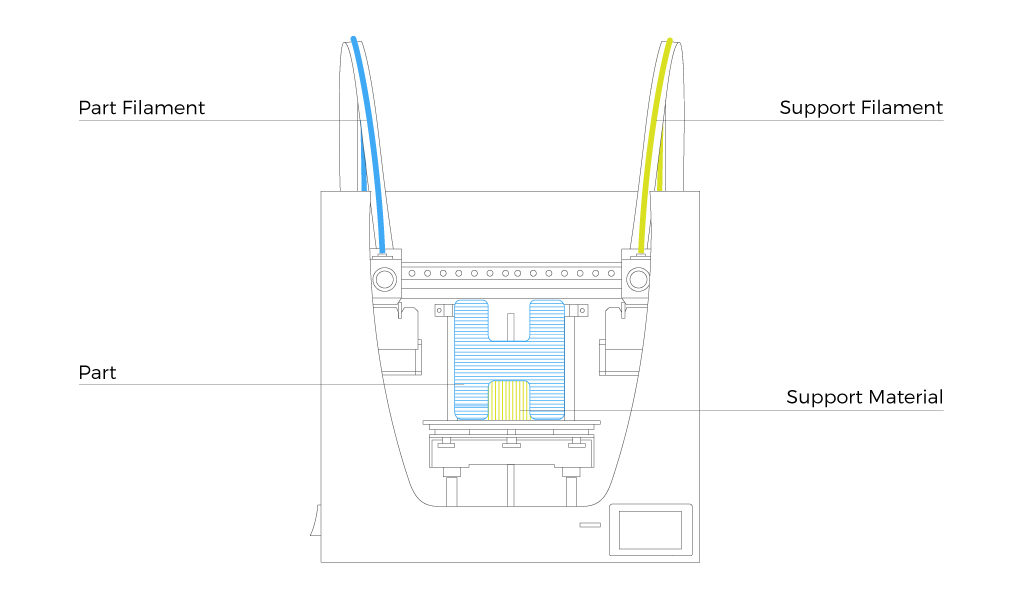

Because of the manufacturing strategy, sometimes it is required to build auxiliary support structures for those models with overhangs shallower than 45º from the horizontal plane.

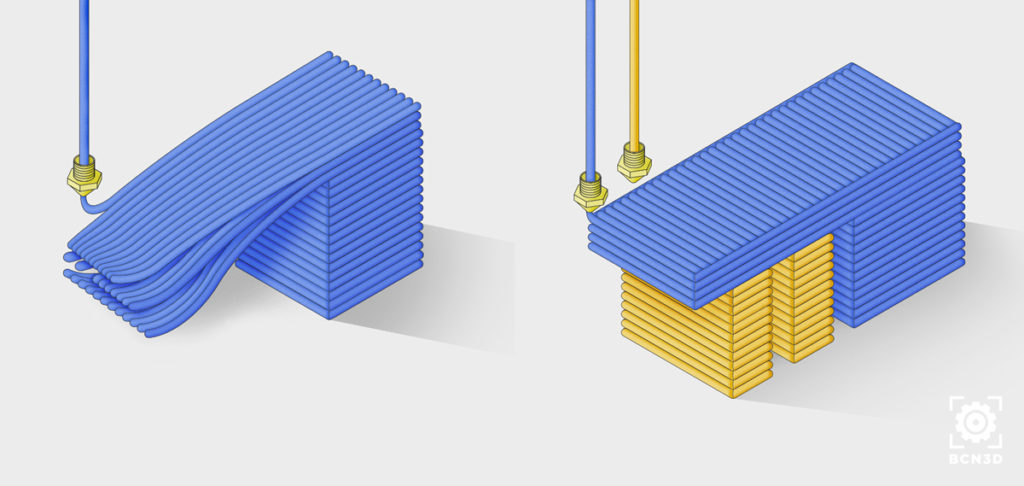

In the case of printers that only have one extruder instead of a dual extruder system, once the model is printed, it is necessary to perform a manual and time-consuming operation to remove the supports. This process affects the quality surface between the model and the supports and also increases the chances of breaking the part. In addition, depending on the geometry of the model it can be impossible to totally remove the supports by hand.

However, BCN3D Technologies proposition has developed an IDEX architecture to counteract the described disadvantage. IDEX stands for Independent Dual Extruder, a unique system that allows to print support structures properly and ensures the finest surface finish. Most of the other printers featuring Dual Extrusion have both toolheads in the same carriage. However, IDEX architecture allows to park the idle carriage aside, preventing the dripping of molten plastic onto the part and improving the overall quality.

Moreover, the IDEX architecture also adds differentiating advantages. First of all, it is possible to combine different materials, like rigid and flexible, or to use two colors to get more attractive or aesthetic models. Last but not least, IDEX opens the door to new printing strategies, allowing to use different tool sizes to cut down printing times without giving away quality.

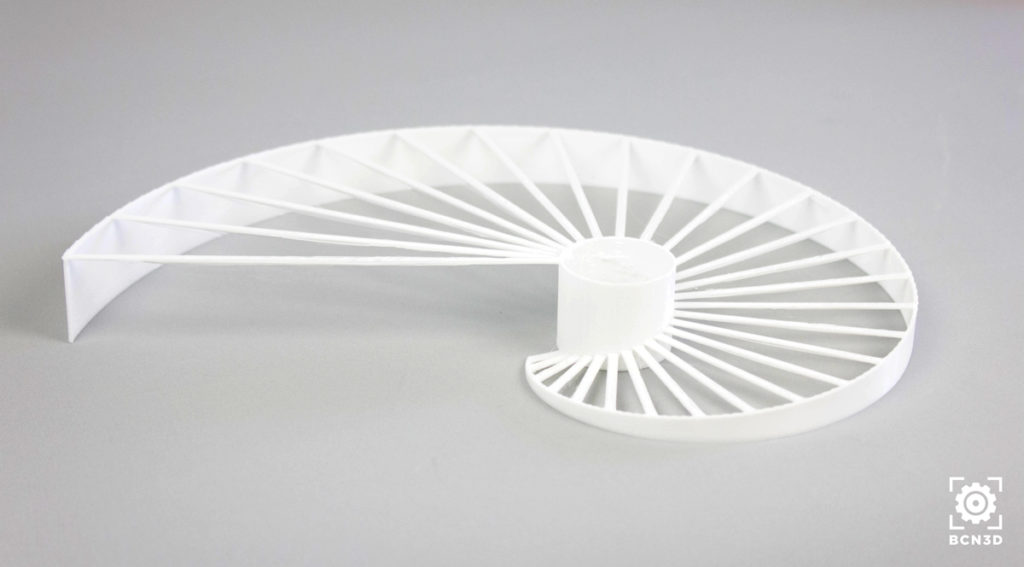

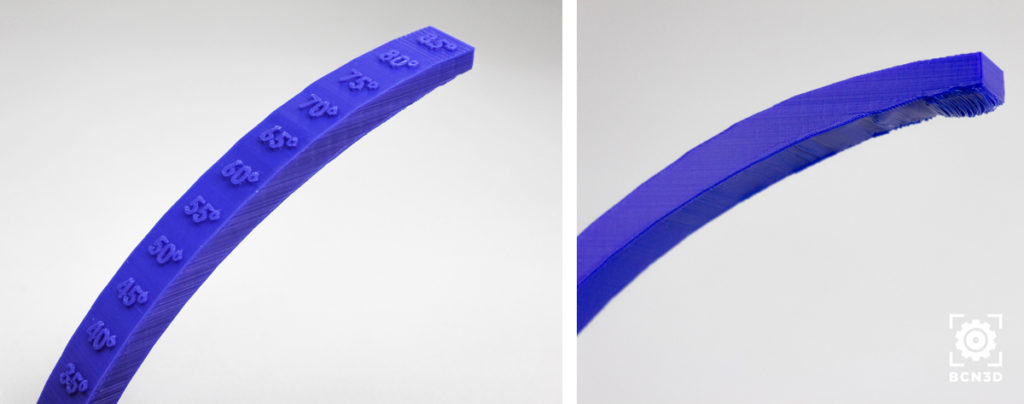

When considering the use of supports in a print, there are two types of structures that are critical. Bridging is a structure between two points at the same height without any solid below. With BCN3D Cura, these structures may be printed without supports if the distance is not too long, and the temperature and speed let the material cool fast and keep its rigidity.

Overhangs are solid parts forming an angle with the normal of the base plane. When this angle is above 45º, supports are in most cases mandatory. But structures with angles between 45º and 80º can be printed without supports, reducing temperature and speed.

In BCN3D Cura we recommend activating the option Generate Support in order to get a better 3D print.

Would you like to better know any of the parameters described? Contact us at info@bcn3dtechnologies.com , we’ll love hearing from you!