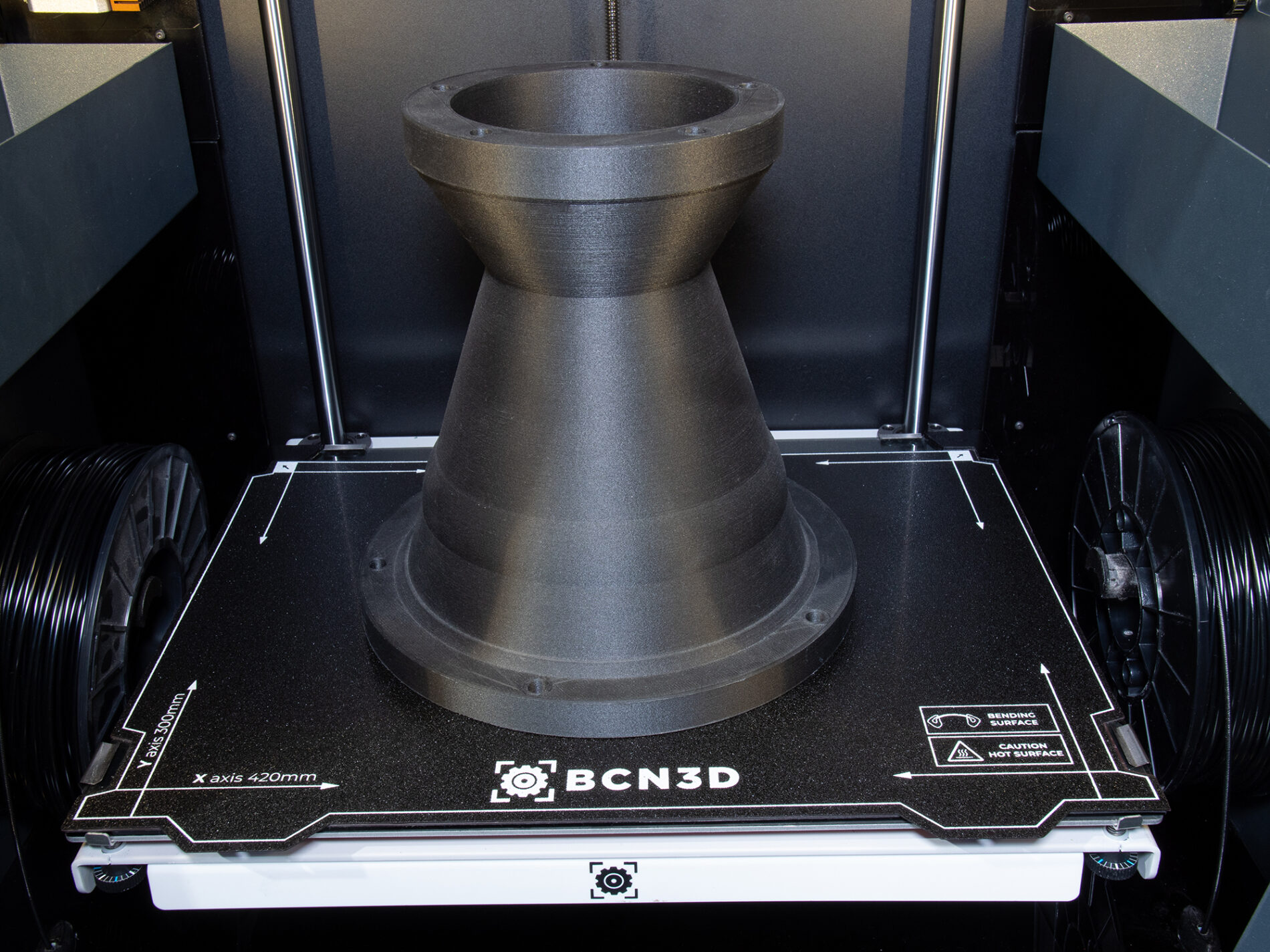

Introducing the Epsilon Flexible Printing Surface for Effortless Print Job Removal

We are pleased to introduce the Flexible Printing Surface, a new product that is compatible with BCN3D Epsilon and Sigma D25 3D printers that are autocalibration enabled. This upgrade offers a faster way to remove print jobs with minimal effort. This not only saves time but also contributes to a smoother workflow, providing users with increased productivity and convenience.

The upgrade consists of a new float glass that has a magnetic sheet attached to it on which the Flexible Printing Surface, a flexible magnetic PEI sheet, is positioned. The user must remove the current glass, which is made of borosilicate, and replace it with this new one. Once the upgrade kit is installed (in place of the standard glass), the Flexible Printing Surface can be switched out as many times as required. This is a consumable part and will wear down overtime at a rate depending on material, cleaning routine and printing temperature.

The option of choosing a float glass was analyzed in depth and several existing options on the market were studied, with float glass proving to be the best option as shown in the study below.

When developing this product, we had to have in mind 3 key aspects:

- Ensure maximum compatibility with the majority of Epsilon and Sigma D25 users. Those users that have autocalibration will be able to use this flexible printing surface upgrade.

We are working on a new firmware version that will also make this product compatible with those users with an Epsilon or a Sigma D25 without autocalibration. At this moment, if you are one of these customers and you can’t wait to use it, you will need to remove the flexible surface each time you run a bed calibration.

If you don’t know whether your printer has autocalibration, you can contact us at sales@bcn3d.com. - Maintaining flatness is a crucial consideration, as it not only reduces the workload for mesh mapping but it’s also essential for printing modes like duplication and mirror print, where mesh mapping is disabled.

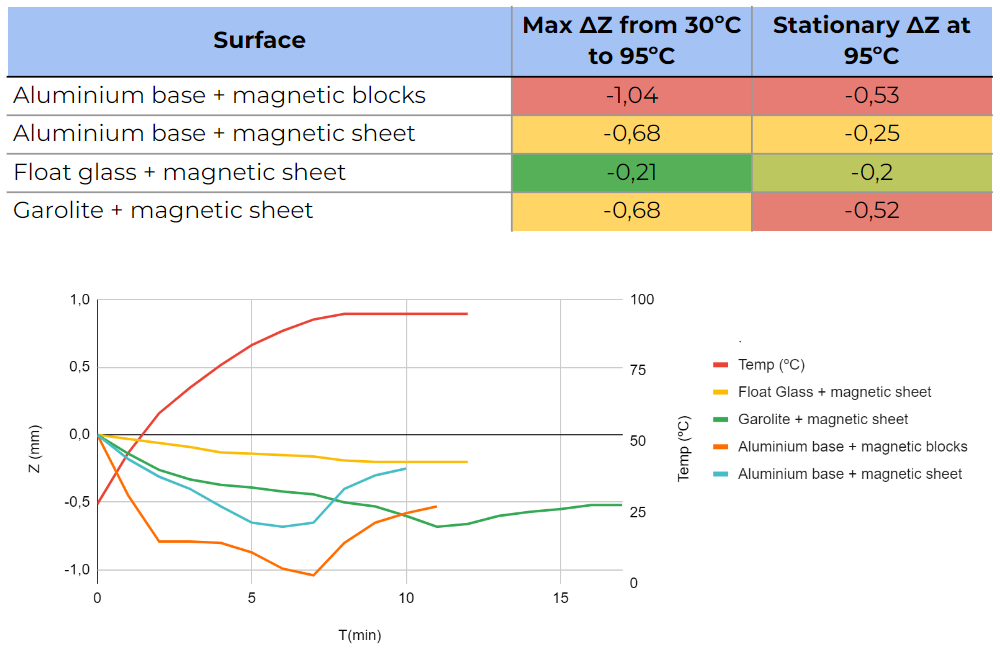

- Ensure the least deviation possible in different bed temperatures, which means less unpredictable movement when heating to different temperatures.

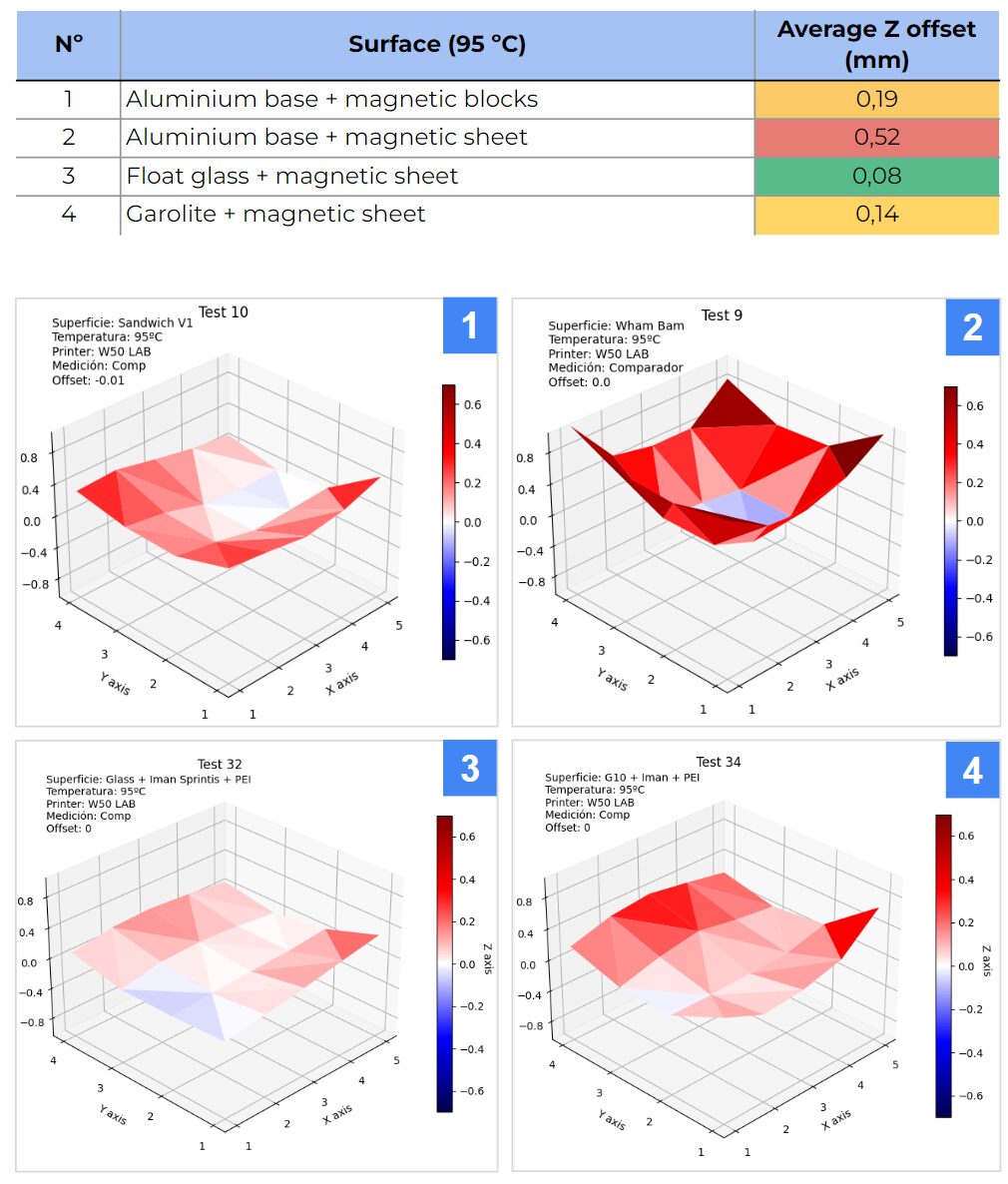

To achieve this, we focused on maintaining compatibility with existing hardware without any modifications. Our process involved experimenting with various base materials to place the flexible printing surface. We specifically assessed the average Z offset across different solutions, representing the average deviation from the center of the build plate.

In this analysis we can see that the float glass option with the magnetic sheet is the one that provides the best Z offset.

- Max ΔZ from 30ºC to 95ºC: Maximum deviation of the center of the surface along the Z axis.

- Stationary ΔZ at 95ºC: Deviation of the center of the surface along the Z axis at 95ºC compared to 30ºC. Less deviation means less unpredictable movement when heating to different temperatures.

After analyzing all the solutions, we determined that float glass is the best option. It ensures a consistently flat print surface and exhibits minimal deviation when exposed to various temperatures.

On our latest Stratos version, the 2.0, users will need to select the option for the flexible printing surface when slicing a print job. In this article from our knowledge base, we explain all the details on how to install and configure it. The new flexible printing surface is available as an upgrade kit, which includes float glass with the magnetic sheet and the flexible surface, or as a consumable, which only includes the flexible surface.

Considerations:

- When performing an XY calibration, users should remove the flexible surface and place the original borosilicate glass to achieve precise and reliable calibration.

- The flexible surface is not compatible with metal filaments due to their significant thermal contraction. Therefore, the original borosilicate glass is essential for optimal performance.

Users interested in the new flexible printing surface can acquire it through their nearest BCN3D distributor by 1st February.