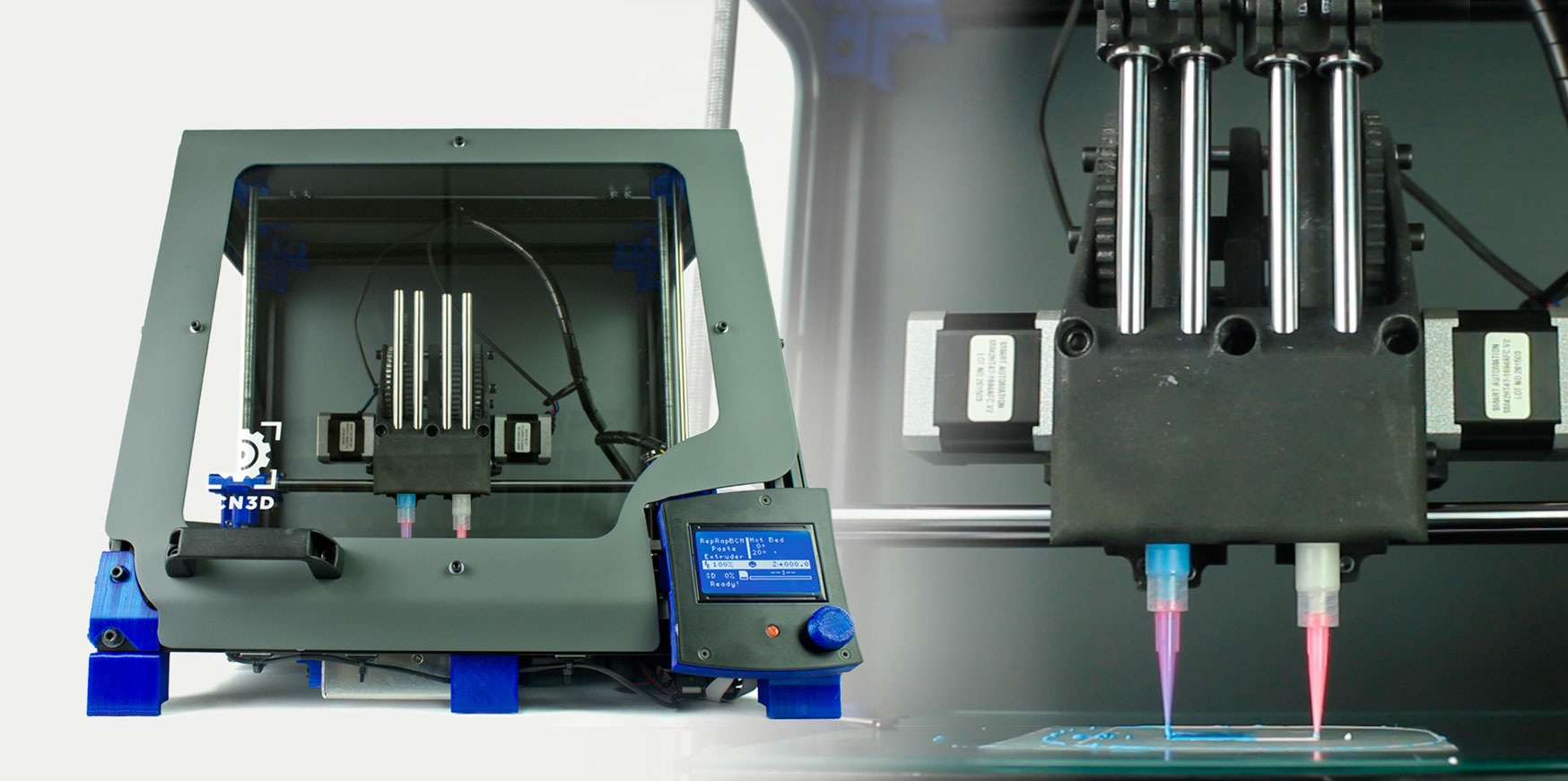

Dual paste extruder, last of the upgrades for the BCN3D+

The investigation team from the Fundació CIM-UPC, BCN3D Technologies alma mater, has developed a dual paste extruder able to print a wide range of ceramic materials.

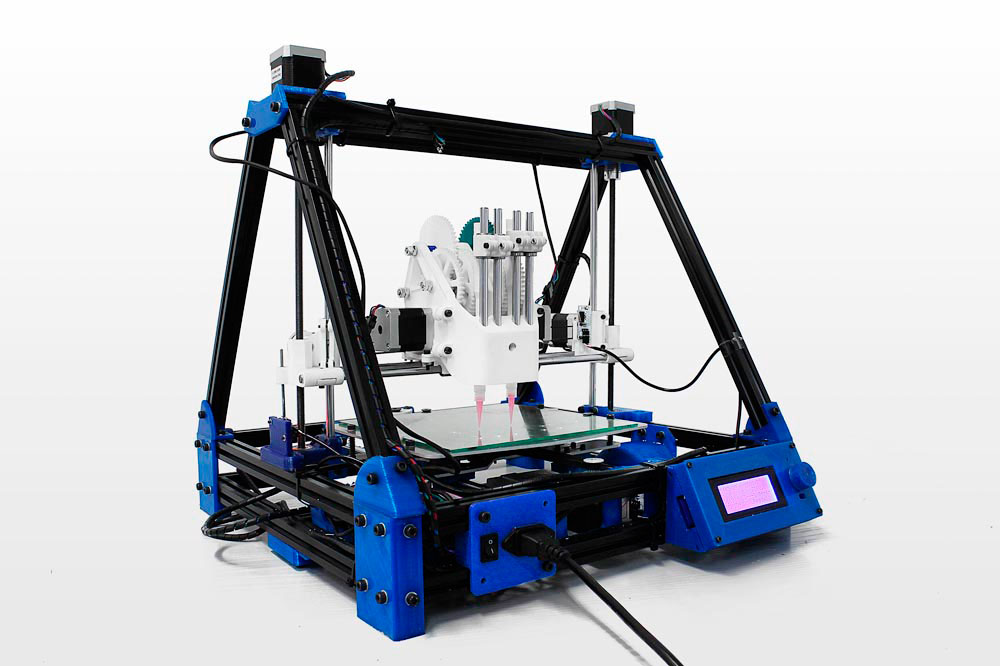

The BCN3D+, as the printer chosen for the project, is characterized by its great modularity, which allows applying on it several structure modifications in order to include a dual paste extruder, that has become very attractive for many universities around the world. This upgrade lies in a double head able to adapt to three, five or ten cubic centimeters syringes.

The BCN3D+ equipped with this dual paste extruder can print any paste material, as long as it needs an extrusion force equal or lower than 100 Newtons. It should be taken into account that the head can not be warmed, so the material used for the printing must be soft enough to extrude it at room temperature. However, we preserve the BCN3D+ heated bed, which can be warmed up to 80ºC.

With these characteristics and applications, the dual paste extruder developed by Fundació CIM-UPC is very attractive to entities working on different investigation and technology branchs. The Central European Institute of Technology (CEITEC) from Brno University of Technology from Czech Republic or the Centro de Investigación en Nanoenginyeria from UPC are two examples.

Nowadays, we offered the dual paste extruder to different universities around the world that had shown interest for the product. Printing technical ceramics or hydrogels are some of the applications of the dual paste extruder, easing the development of several investigation projects.

On the other hand, the dual paste extruder could have very interesting applications in other areas, like cooking, where 3D printing already has presence.

With this advance, the BCN3D+ becomes, once again, as the modular printer par excellence within the wide product range designed and developed by BCN3D Technologies.