BCN3D Slicing Guide 6: Top tips for build plate adhesion proficiency

For Number 6 in the slicing guide series by FlowalistikxBCN3D, we take a look at the essential considerations of your part’s build plate adhesion. This white paper features a definition of build plate adhesion, all uses and types of adhesion, the helpful settings you need to know, and how to overcome any potential issues.

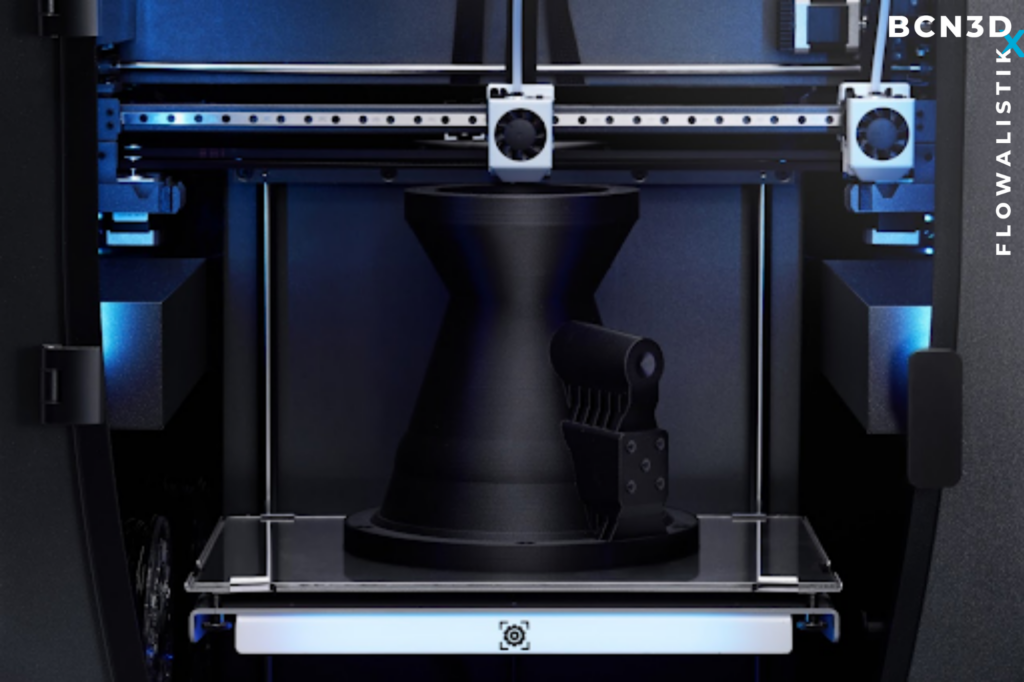

The build plate adhesion is the first step to a successful print. Each additive manufacturing process has different capabilities and limitations, but most technologies share a common rule: The initial layer must be perfect to guarantee a great 3D printing experience. This white paper equips you with the knowledge to make this stage in your printing process a breeze.

What is Build Plate Adhesion?

Build Plate Adhesion – also known as Bed adhesion – refers to the group of settings and 3D printer components whose primary purpose is to guarantee the adhesion of the initial 3D printed layer to the build plate.

Common adhesion issues

Build plate adhesion issues can be frustrating. Many different variables affect the 3D printing process, but they usually fall into one of the following categories when it comes to adhesion issues.

Build plate leveling

If you have build plate adhesion issues, bed leveling is the first thing to check. If the build plate is not level, one side of it will be closer to the nozzle than the other, producing inconsistent build plate adhesion.

Unclean build plate surface

An excellent build plate adhesion can only be achieved with a clean surface. Checking the build plate and cleaning it with alcohol and a microfiber cloth after some prints is part of every efficient 3D printing workflow.

Wrong slicing settings

Different slicing settings affect build plate adhesion, including print speed, temperature control, and even line width. The most important ones are explained below in the white paper.

Types of Build Plate Adhesion

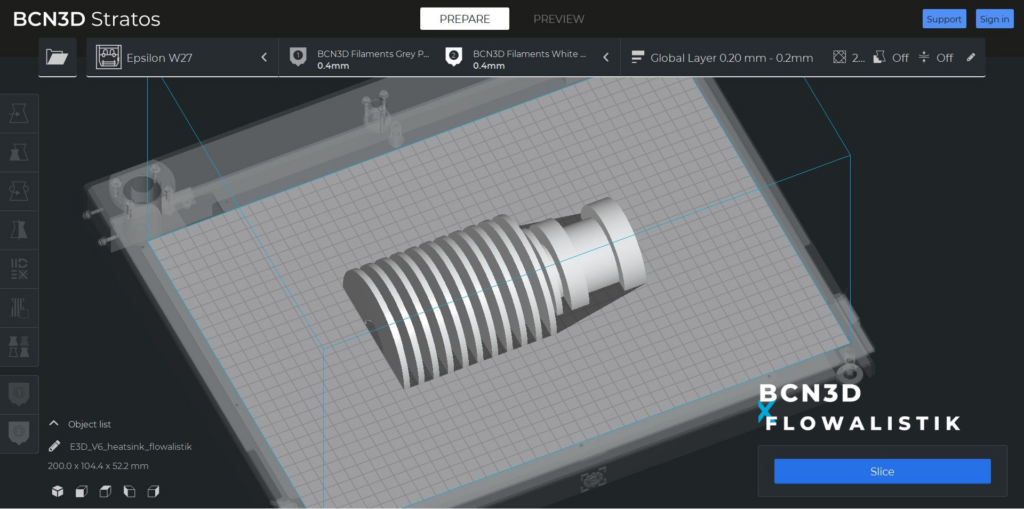

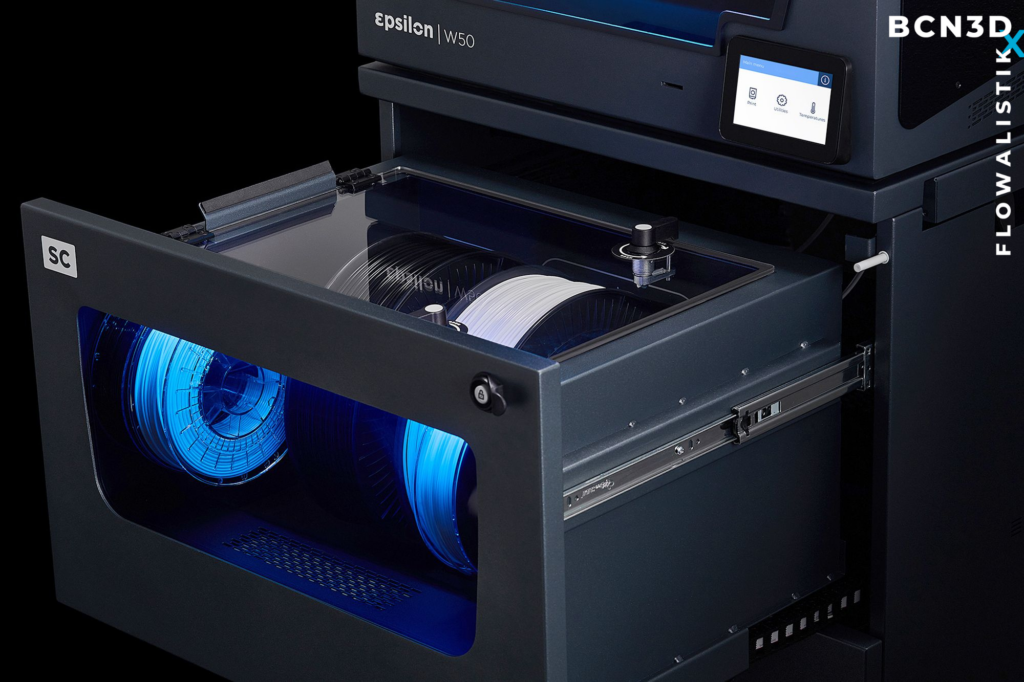

In BCN3D Stratos, you can find four different options that can help you improve both priming the extrusion and the build plate adhesion.

None

When this option is selected, the 3D printing process starts as soon as the temperature is reached and the material is purged.

Skirt

The skirt is a line printed around the model but not connected to it.

Even though this option doesn’t directly affect build plate adhesion, it can prevent issues in those cases where insufficient material is purged before the print starts.

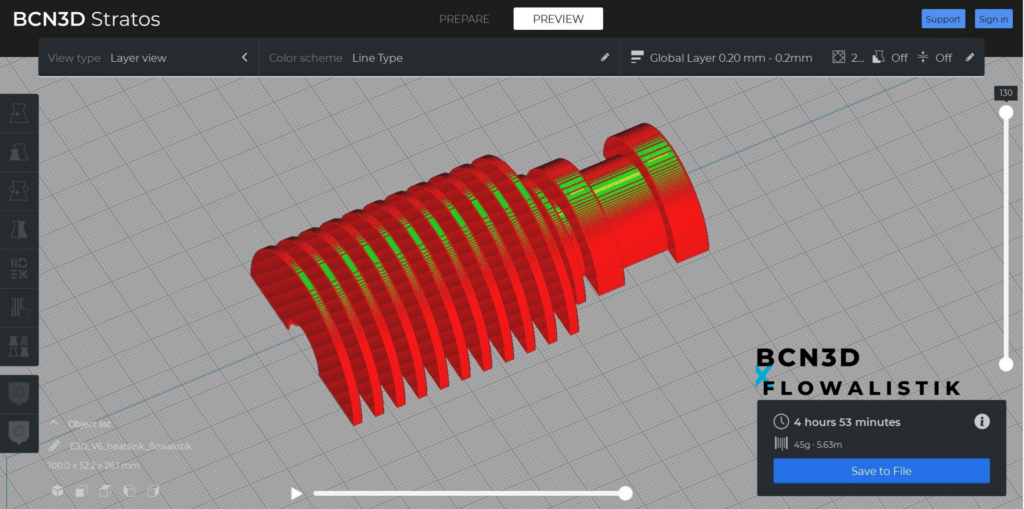

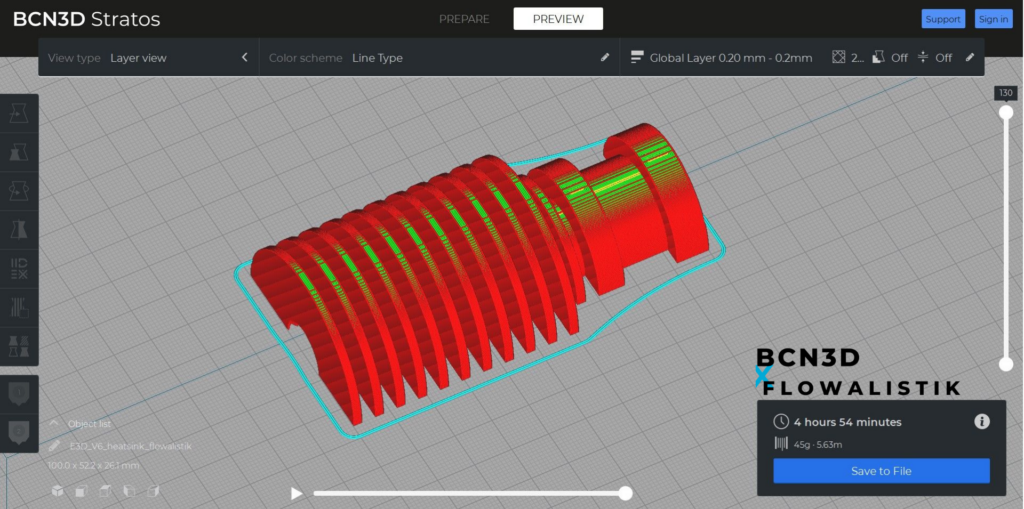

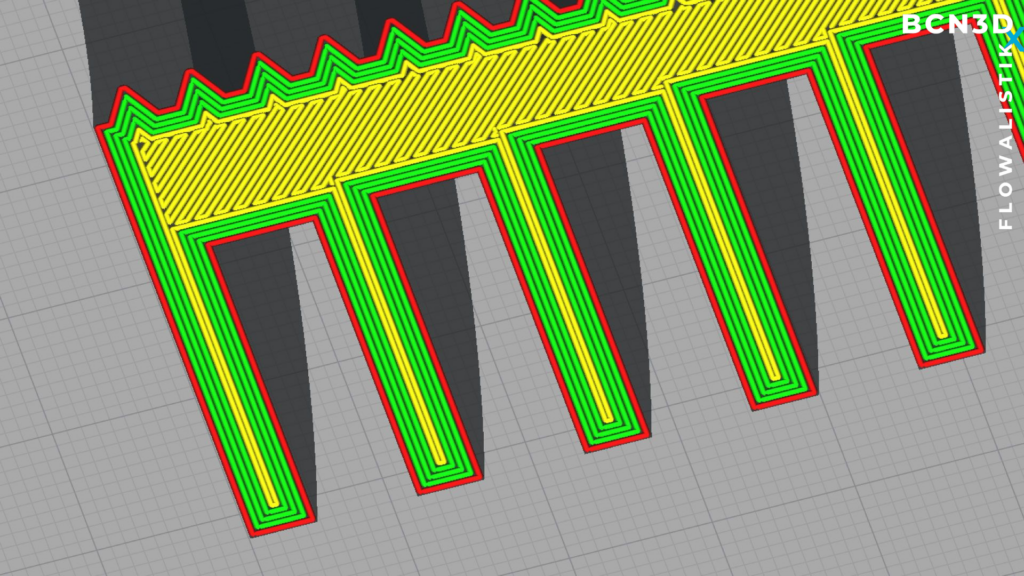

Brim

The brim adds a single layer of flat area around the base of the model, preventing warping.

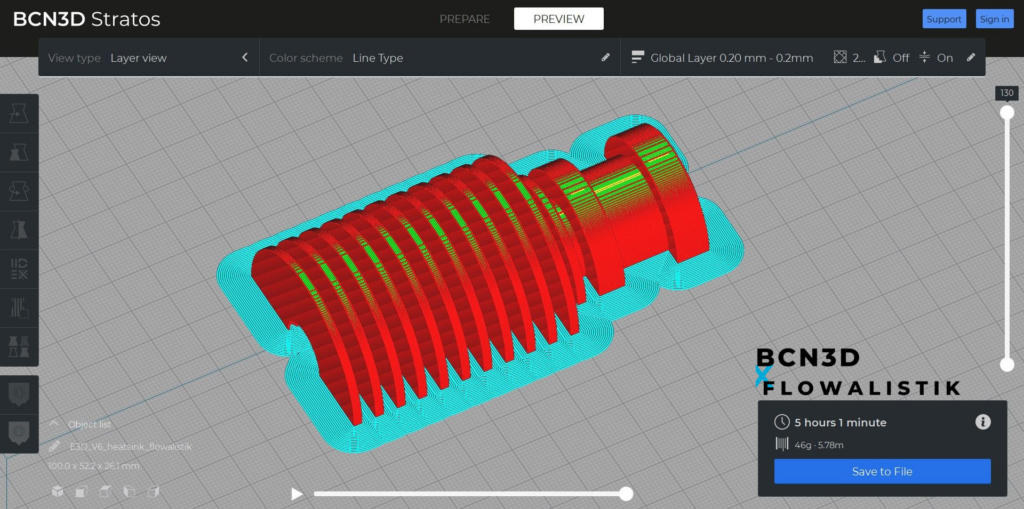

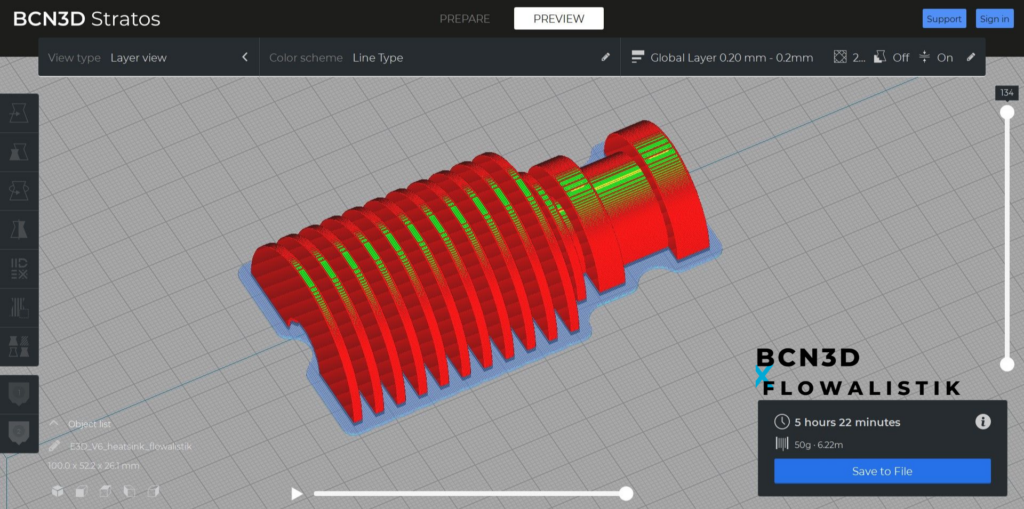

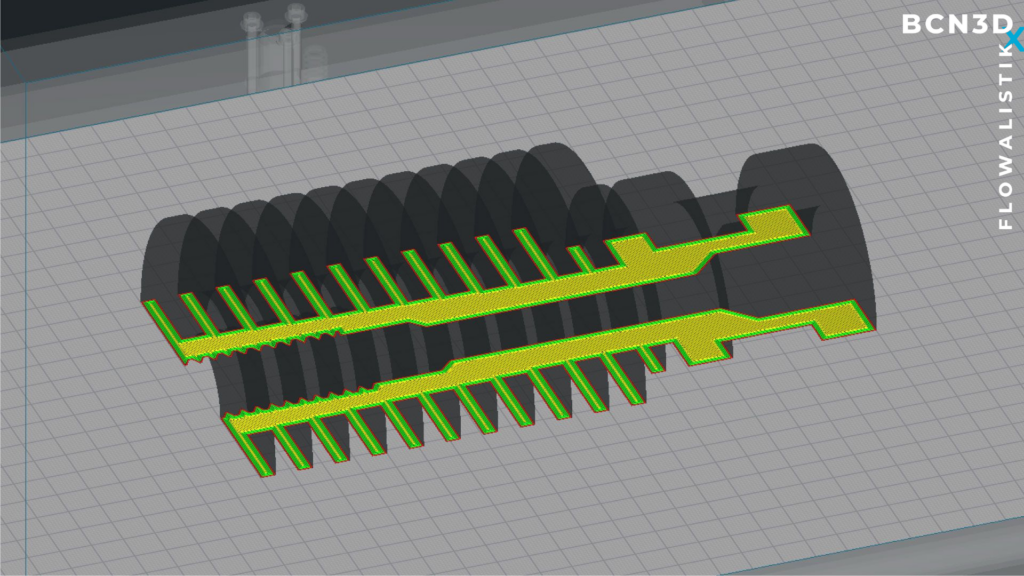

Raft

The raft adds a thick grid with a roof below the model, which guarantees a good build plate adhesion.

Essential build plate adhesion settings

BCN3D Stratos includes many different features that affect the build plate adhesion. Find the most relevant ones below.

Initial Layer Height

A thicker Initial Layer usually makes adhesion to the build plate easier. However, if the layer is too thick, the nozzle may not be close enough to the build plate.

Initial Layer Line Width

This setting multiplies the standard line width on the first layer. Increasing this setting usually improves build plate adhesion.

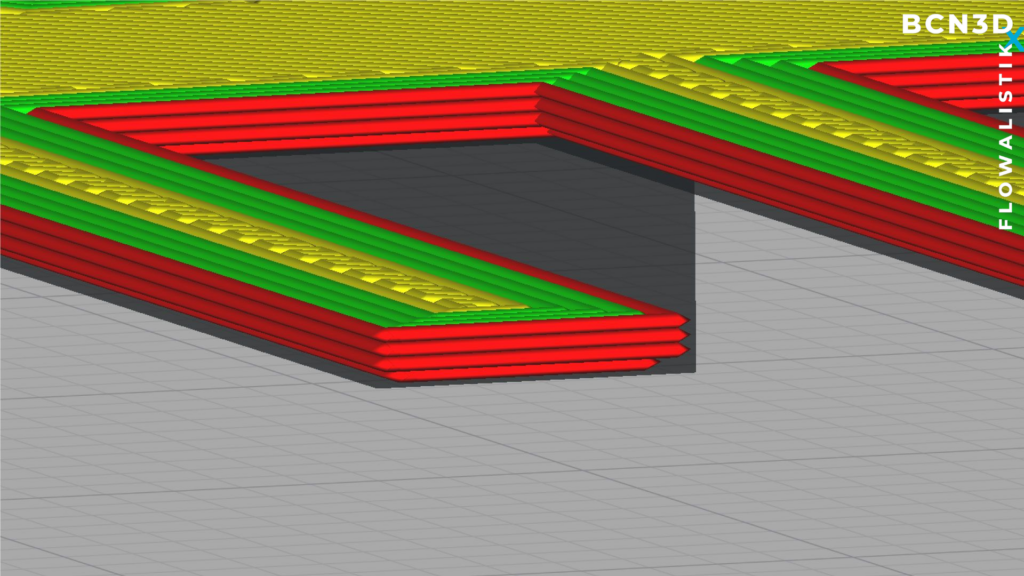

Initial Layer Horizontal Expansion

This setting is handy if the elephant foot issue affects your 3D printed parts. This issue expands the initial layer outwards affecting dimensional accuracy, although it increases the build plate adhesion.

Initial Layer Print Temperature

In BCN3D Stratos, you can adjust the print temperature of the initial layer. To improve the build plate adhesion, it’s recommended to use a slightly higher temperature for the initial layer.

Build Plate Temperature

Each 3D printing material has a different recommended build plate temperature. It’s always recommended to check the recommended print settings and adjust them in BCN3D Stratos.

Initial Layer Speed

A lower value is advised to improve adhesion to the build plate. For example, the recommended Initial Layer Speed is at least 50% slower than the standard print speed.

In conclusion, optimizing your build plate adhesion is a vital stage in your printing process. We’ve touched upon common adhesion issues, types of build plate adhesion and, essential build plate adhesion settings. To read about these topics and more related factors in detail, don’t hesitate to download our specialized white paper or all-in-one ebook featuring all 6 of our slicing guides below.