BCN3D Omega I60: How Does the Active Heated Chamber Work?

The Active Heated Chamber facilitates the fabrication of engineering polymers by maintaining an ideal temperature for the part throughout the printing process. In this article, it is explained how the heated chamber works and what stability is achieved throughout the entire printing process within the chamber.

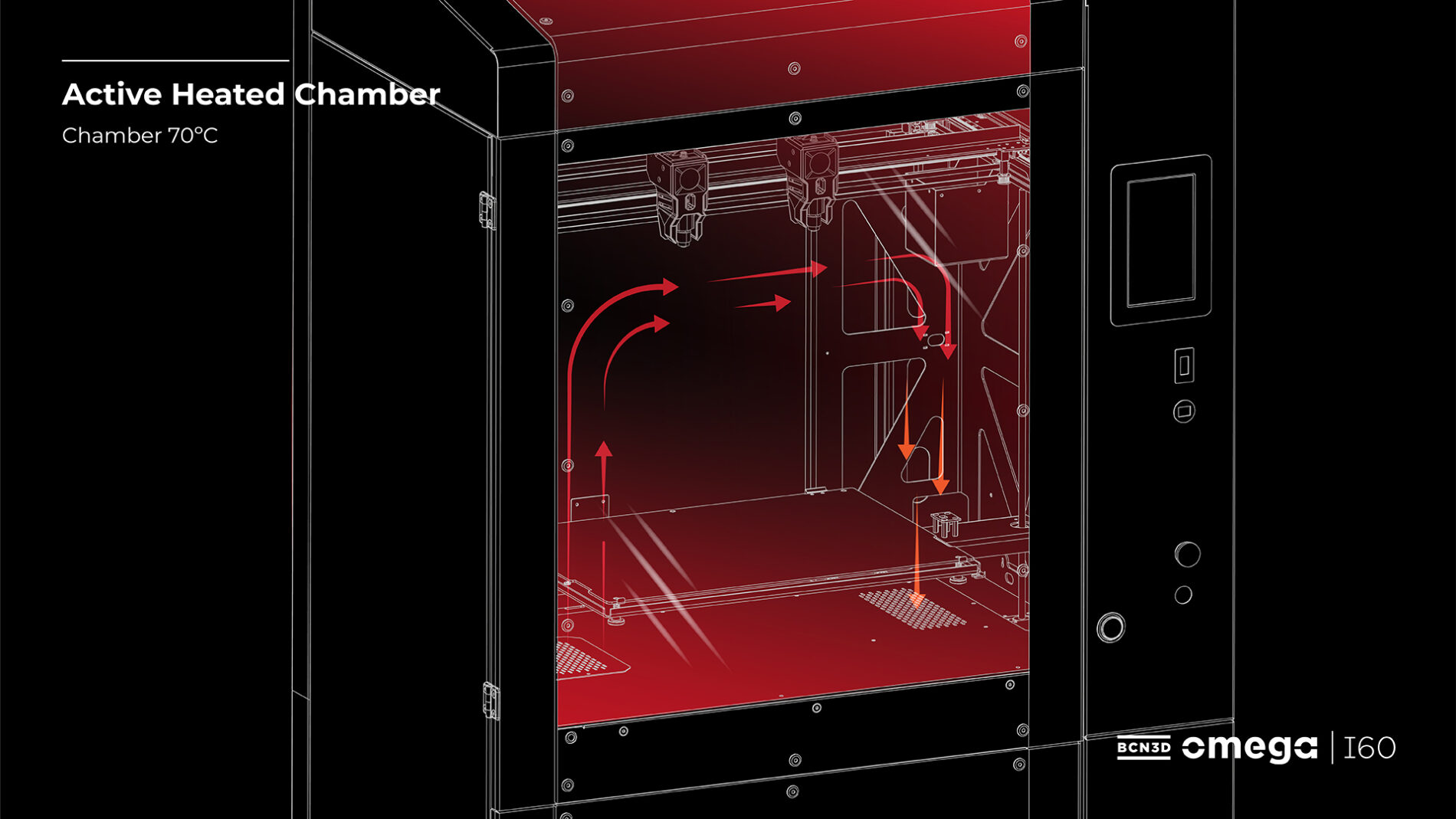

The Omega I60 features a heating duct that filters and heats the air in the printing module and can reach up to 70ºC (158 ºF). A heated chamber facilitates the manufacturing of engineering polymers by maintaining an ideal temperature for the printable part throughout the printing process. This temperature control ensures the uniform construction of the part, minimizing the formation of internal stresses. Heating the chamber promotes relaxation and eliminates internal tensions during manufacturing, effectively preventing issues like warping and cracking. All of this ensures the best dimensional accuracy and mechanical durability for the printed part. The BCN3D Omega I60 heated chamber can reach temperatures of up to 70ºC (158 ºF), making it ideal for printing materials such as ASA, PA, ABS and reinforced PA, among others.

Given the wide range of materials, the most effective way to ensure the proper printing of any polymer not included in the BCN3D portfolio or the Open Filament Network is by understanding how the heated chamber works. Therefore, we provide an analysis of the temperature across the print bed and throughout the entire volume that the part can occupy.

Temperature Test

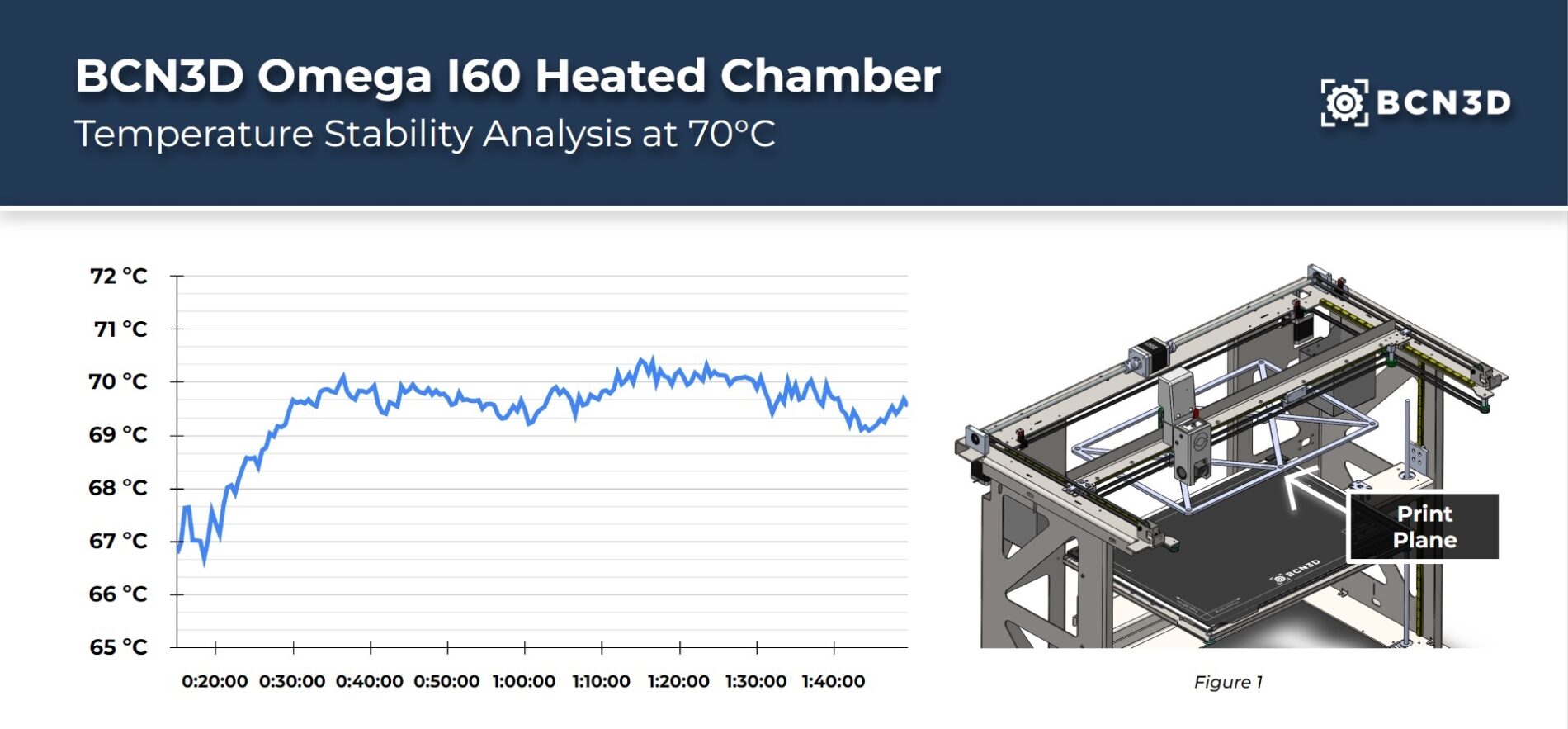

Starting from an ambient temperature of 20ºC, once the Heated Chamber reaches the target temperature of 70ºC, the average temperature of the print plane (Figure 1) is within a margin of 70ºC +/-1ºC, as shown in chart below.

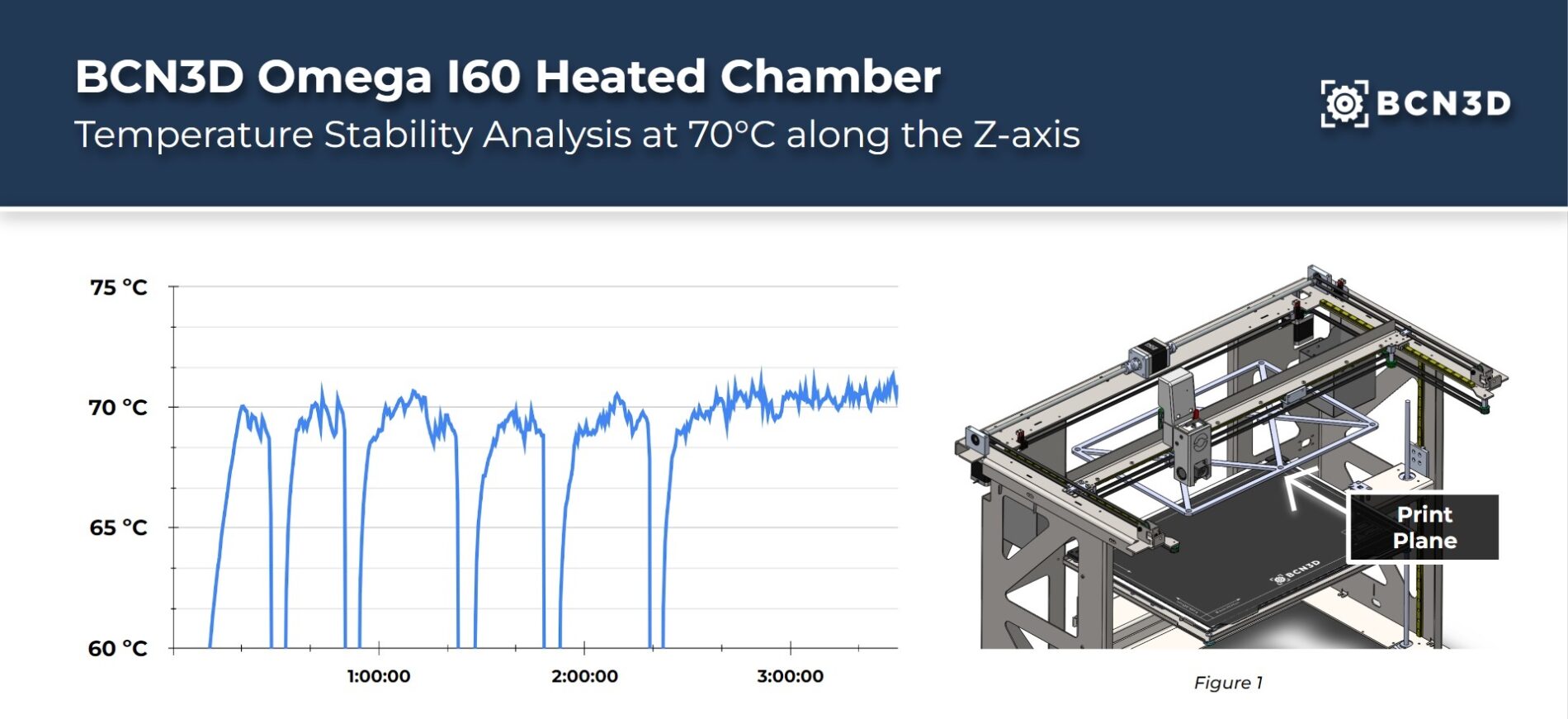

To measure the rest of the print volume, the position of the measurement plane was changed along the Z-axis. As seen in the following chart, the average temperature of the print plane remains constant over six height changes, with a maximum variation of +/-2ºC.

For lower Heated Chamber temperatures and high HotBed temperatures, there may be a temperature deviation on the print bed of +5ºC.

Finally, the airflow generated by the heating system of the Heated Chamber does not exceed 0.5 m/s over the print volume.

Remember that when printing, the recommended print profiles in BCN3D Stratos take into account the influence of the Heated Chamber and the HotBed on the part, so it is always optimal to use them or use them as a base to ensure proper printing with engineering materials.

Conclusions

- At 70ºC, the temperature in the print volume is homogeneous with a variation of +/-1ºC.

- Below the maximum temperature, the HotBed affects the temperature on the print bed by up to +5ºC when the Heated Chamber is set to 50ºC.

- The airflow from the heating duct of the printing module can be considered negligible.

- BCN3D Stratos includes optimized print profiles for the fabrication of parts requiring the Heated Chamber.