Additive manufacturing helps isolate cells from aggressive breast cancers

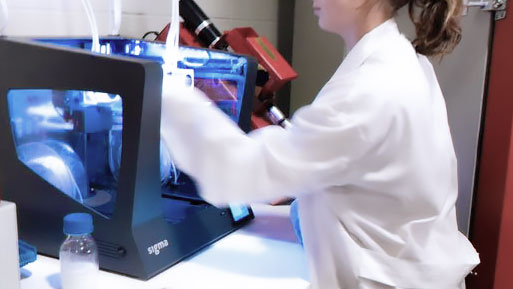

Using additive manufacturing, scientists from the University of Girona have successfully isolated breast cancer cells. Using their BCN3D Sigma 3D printer, the team manufactures 3D scaffolds to recreate structures in body tissues and fibers for study and research purposes.

A research team from the University of Girona has managed to isolate stem cells from one of the most aggressive breast cancers, by using additive manufacturing. Their goal is to facilitate investigation and eventually find a drug that exclusively attacks these cells without damaging healthy parts of the body, therefore preventing patients from suffering relapses.

Dr. Teresa Puig, one of the researchers leading the project, explained that tumor cells remain in the body after chemotherapy and radiotherapy treatments, and are responsible for the reappearance of the disease. The cancer being researched in this case, is the triple negative subtype, which occurs in young women and leads to relapses within three or four years in 20-30% of patients.

“A tumor is made up of many types of cells, and these are the cells we have in low proportions. Therefore, it is complicated to locate these cells within the tumor. This new system is cleaner, allowing us to work more directly with these types of cells,” says Teresa Puig, director of the Oncology Unit of the Group for the Investigation of New Therapeutic Targets.

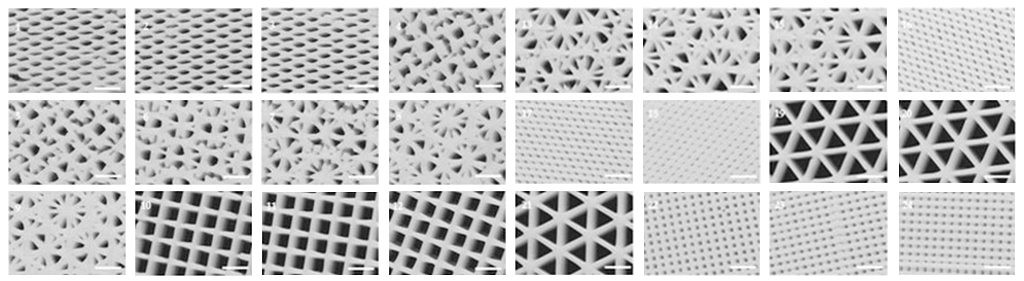

The main objective of the project is to develop a scaffold architecture which stops a high breast cancer cell proliferation rate. For this reason, different values of the parameters were tested using the BCN3D Cura slicing software.

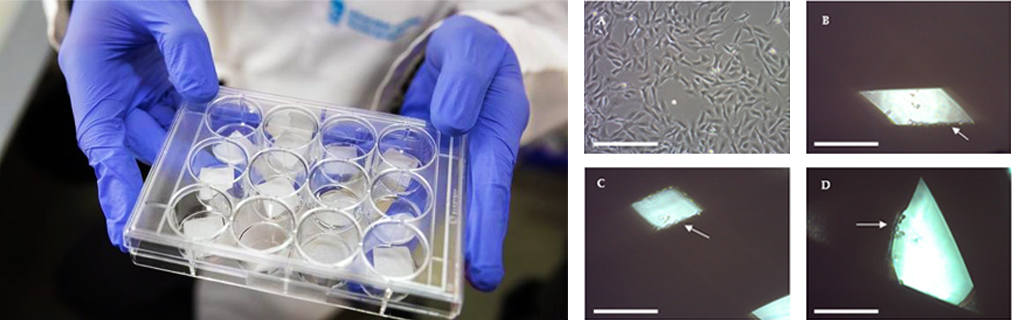

To test which geometric form was most effective in separating the cells, several parameters (layer height, infill density, infill pattern, infill direction, and flow) were tested on the BCN3D Cura slicing software to find the optimal values, which were then printed using a BCN3D Sigma printer.

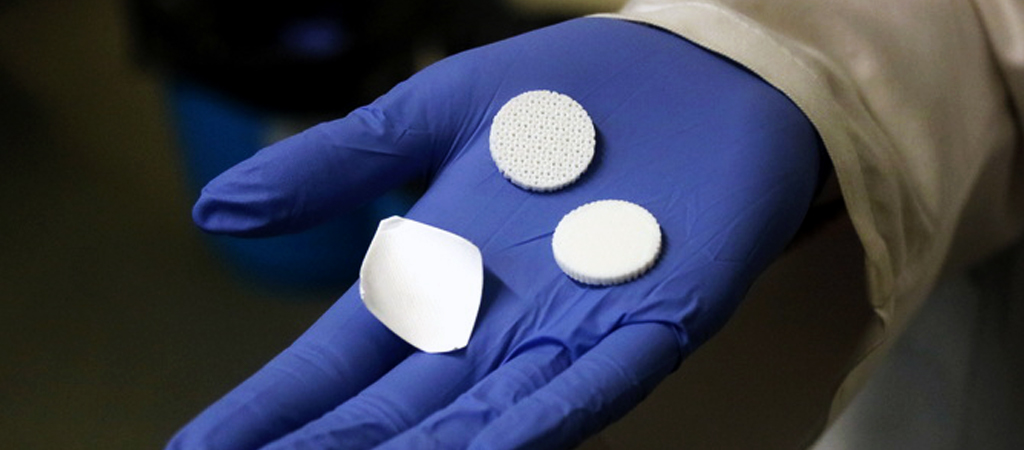

Using the Taguchi experimental design method, twenty-seven scaffold configurations were manufactured and then analyzed. To perform the characterization and cell proliferation assays, at least ten copies of each configuration were printed.

“This structure is a mesh that, on the basis of a series of parameters such as porosities, spaces, and the distance between one element and another, is ultimately able to allow cells to stick to the matrix or not, to grow, and to be able to ‘enrich themselves’,” explains Joaquim de Ciurana, director of the Research Group on the Engineering of Products, Processes, and Production.

Prior to this investigation, these cell structures were produced two-dimensionally, meaning that the cells were not effectively separated and specific pharmaceuticals could not be produced in order to attack them.

With this new technology, the researchers will be able to study the cells in greater depth to find the bio-indicators responsible for the tumors and find out how to treat them.

“Although we still do not know how to treat them, we have found a way to isolate them,” says Teresa Puig.

Due to the focus on 3D printing technologies, the project has been named ONCOen3D. By using additive manufacturing, the team reduced the costs of the traditional methodology of analysis, and therefore increased the experiments carried out with cancer cells.

The results of the study have been published in the scientific journals ‘International Journal of Molecular Sciences’ and ‘Polymers’, and have been presented at international congresses. The research has been funded in part with money from La Marató de TV3. In this document, a detailed report on the investigation can be found.

[typography font=”Montserrat” size=”10″ line height=”10″ size_format=”px”]Source: Article posted on the International Journal of Molecular Sciences by Emma Polonio-Alcalá, Marc Rabionet, Antonio J. Guerra, Marc Yeste, Joaquim Ciurana and Teresa Puig. “Screening of Additive Manufactured Scaffolds Designs for Triple Negative Breast Cancer 3D Cell Culture and Stem-Like Expansion”.[/typography]