3D Port: A sustainable production on-site and on-demand

Every 4 seconds, humanity pours 1000kg of plastics into the sea, causing the extinction of marine animals, the death of corals and reefs, the destruction of entire ecosystems, among other irreparable damages. Even if we were able to educate the consumer, establish rigid laws and enforce hard fines, there would still be one problem to solve: the 260.000 tonnes of plastic that remain in the sea.

Most of the solutions to this problem are based on decentralized recycling systems and are very focused on the collection of plastics, ignoring its reuse. The carbon footprint resulting from such a decentralized process is worse for the planet than not recycling those plastics. Plus, a long value chain results in a higher end product price. So, the cure is worse than the disease.

3D Port is a start-up that offers a centralized ecosystem, which allows sea waste to be transformed into 3D printed long-term useful products. The Port of Barcelona has been selected to host our first pilot test because it is the nerve center of the logistics of the city and gives us direct access to the sea waste. We’re creating a hub that embraces the whole transformation process of plastics and contributes to the blue economy.

The value proposition is based on improving the services that a port can offer to its customers and to the city. Either through enhancing the capabilities of its facilities and shipyards by producing customized products, spare parts and tooling or directly by offering a space to its customers where they can have customized and 0km production services. The large number and variety of parts that make up the maintenance of a port (including its stakeholders) results in large catalogs of thousands of products following a long tail model. Being difficult to apply economies of scale in the manufacture of these products, it’s much more efficient to seek local and customized production, greatly reducing the need for stock management and giving rise to an economy of scope.

In conclusion, 3D printing responds to our need for agile on-demand production, customization and personalization of designs and on-site production minimizing logistics costs.

In the past years, we have been developing several products in collaboration with the university Elisava | Barcelona School of Design and Engineering, the shipyard Marina Barcelona 92 and the nautical club Reial Club Marítim of Barcelona.

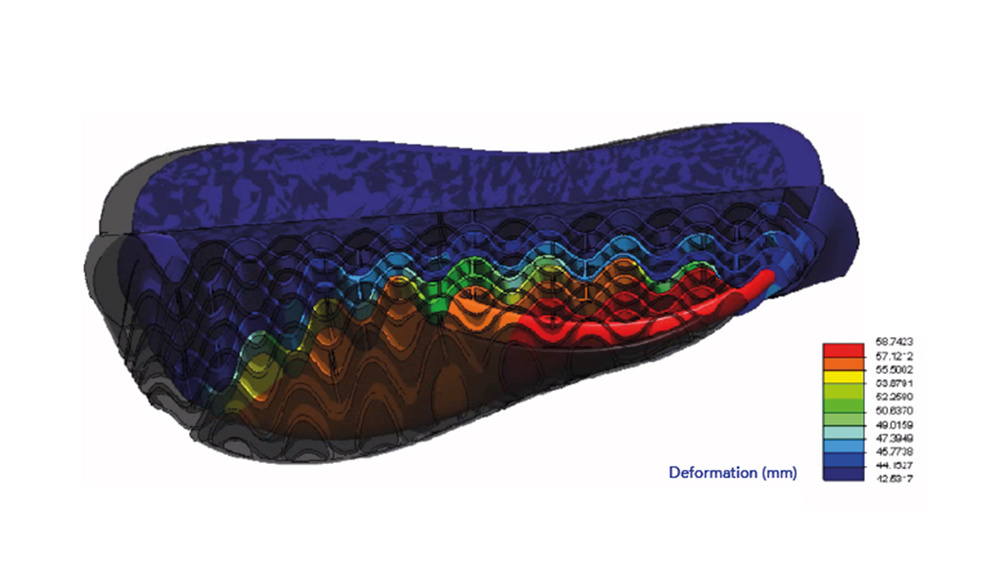

Our most outstanding product is Veluga which is a 3D printed smart dock fender made of recycled plastics collected from the sea. Thanks to its structure, the defense absorbs the impacts of the boats against the pontoon. 3D printing technology allowed us to make the right shape so that the recycled plastic can absorb the force of the boats in the impacts against the dock – achieving a total elastic deformation by means of the small deformation of each curve.

Every unit is made of 5kg of plastics from the sea, which contributes to cleaning the ocean. Veluga’s footprint is on average 60% lower than other conventional fenders, increasing the sustainability of human activity on our planet. Only in Catalonia, there are more than 40 marinas with an average of 250 berths with 2 defenders each, resulting in a potential market of at least 30k units. This market allows us to collect, recycle and revalue a large amount of plastics from the Catalan coast.

For the following 5 years, 3D Port aims to be the main hub for the transformation and revaluation of plastics in the port, focused on 3D printing solutions. At least we hope to have 2 hubs in Spain and another in some other European country.