The ultimate guide to choosing a professional desktop 3D printer

We’ve compiled this white paper to cover all the main features of 3D printers currently on the market, to make your task of choosing the right 3D printer for you a breeze.

The wide range of capabilities offered in the expanding market of 3D printers can be disorientating and, thanks to an incessant interest from the business world, the options continue to multiply. Here’s a glance at the content of our white paper, developed to help you make sense of the key features of 3D printers, in order to find one that fits the needs, goals and requirements of your company.

Size matters

Build volume refers to the maximum size of a model that a 3D printer can produce in a single print. This is a super important factor to consider when your company requires the printing of large parts. Be aware that the ability to produce large objects may generate a loss in accuracy and reliability, and an increase in the price of the print overall.

Layer by layer

Layer height is the distance between one layer and the next.The layer resolution determines the quality on the Z-axis, and typically ranges from 0.05mm to 0.5mm:

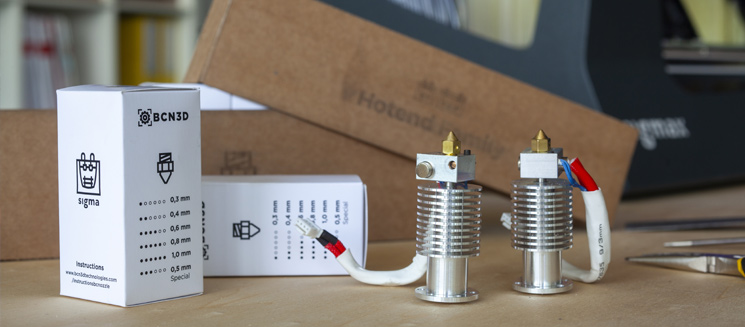

Picking out hotends

A hotend is the component of an FFF 3D printer that heats, melts and extrudes the material layer by layer through a nozzle. Your hotends determine which materials you can use, and the size of the nozzle defines the resolution on the X and Y axis. The better the quality of the hotend, the better the printing!

You can learn more about hotends in our Anatomy of an Extrusion System.

Ensuring extruders do their job

An extruder is the motor and associated mechanisms that push and pull the filament to carry it from the spool to the hotend. There are two types of extruders:

Doubling productivity with dual extrusion

Dual extrusion refers to the ability of an FFF 3D printer to use two different filaments in a single print job. There are currently two types of Dual Extrusion on the 3D Printing Market:

Our white paper goes into more detail on what’s mentioned above, and looks through even more aspects to take into consideration:

- printing speed

- compatible materials

- print surface

- firmware

- slicing software